What Are Zero Clearance Table Saw Inserts?

In case you're not familiar with a zero clearance insert, we'll explain what this handy accessory is and what it does.

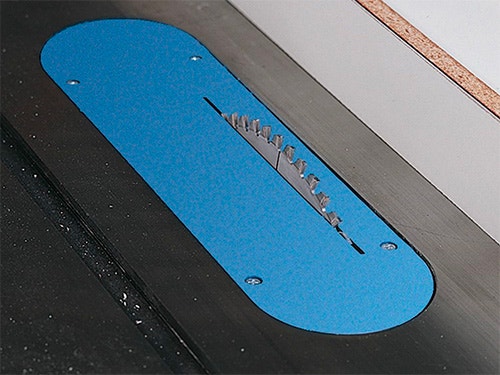

If you're having trouble with tear-out on the bottom edge of you table saw crosscuts, or you've experienced the sudden shock of a narrow piece of drop-off wedging in between the saw blade and the opening in your saw's throat plate, someone may have already advised you to get a "zero clearance insert". A zero clearance insert is a substitute for the throat plate that came with your table saw. The opening in the insert is cut on the table saw to the exact width of the saw blade's kerf, thereby preventing thin slices of wood from jamming in between the blade and the throat plate during a cut, and reducing the amount of tear-out that can happen with a standard insert.

The fact that there's such a thing as a zero clearance insert - and that you could probably use one if you do any amount of exacting table saw work - doesn't mean that the throat plate that came with your saw is poorly designed. It has to allow clearance for the saw blade over your saw's entire range of possible bevel angle settings, and therefore will always leave some amount of gap. In many situations, a little space between the insert and the blade isn't a big deal. The insert that came with your saw will work just fine much of the time, and makes changing bevel settings quicker for cuts where small cut-off and perfectly clean cut-edges aren't a concern.

In fact, you might call that the "zero clearance tradeoff": The whole point of a zero clearance insert is to bring the distance between the blade and the nearest supporting surface down to nothing, and as a result, every zero clearance insert is good for one, and only one, bevel angle setting. Fortunately, zero clearance inserts aren't hard to come by, and most of us do most of our cutting at a few common angle settings, anyway. Having a 90 and 45 degree insert on hand is a good start, and more can be added without too much trouble as the need arises.

You can make your own zero clearance inserts; the process isn't difficult. What material should you use? Hardwood is a possibility, but remember that the insert has to fit into the opening on your saw precisely, and also needs to sit perfectly flush with the surface of the saw. And while your table saw will stay the exact same shape and size with seasonal fluctuations in humidity, your hardwood table saw insert may not. It's also important to use a material that will lay perfectly flat, provide a smooth, low friction surface, and has some resistance to wear, making wood, plywood and MDF less than perfect choices.

Sheet material made from phenolic resin is the current material of choice for woodworking jigs and fixtures of all sorts, and is the perfect material for a zero clearance insert. It lays flat, provides rigid support and wears like iron, but still can be machined using the tool you already have in your shop. In fact, most after-market throat plates are made from phenolic, including Rockler's ready to use Zero Clearance Inserts. Rockler inserts are available in the most common throat plate sizes and come complete with pre-installed leveling screws. All you have to do is drop them into your table saw.

If you don't find your saw on the list, or you'd prefer to make your own inserts in exchange for considerable savings, there's another option: Rockler's Phenolic Table Saw Insert Kit. You'll get two 1/2" x 3-7/8" x 14" phenolic blanks, enough to make a 90 degree insert and one at the bevel angle you use most. The kit lets you take advantage of the benefits of rigid, low friction phenolic material at around half the cost of a pre-made insert and with a minimal time investment: The insert that came with your saw makes the perfect template. Just stick it to the blank with double sided tape (trim off the excess at the corners on a band saw first, if you'd like) and cut it to size with a flush trim router bit. You can make a couple of inserts in about a half an hour. And to speed up the process even more, pick up a Phenolic Countersink Drill Bit. This carbide drill bit is specially designed to bore holes for leveling screws, and cuts through the tough phenolic material quickly, cleanly and with no wander.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks