Woodworking Tools Angle Scales and Terminology

Not all woodworking machinery angle scales are created alike. In fact, there are two different conventions for the calibration of angle scales in common use on woodworking machinery. One type of scale is calibrated to treat a square cut as a 90 degree cut, while the other scale treats a square cut as a 0 degree cut. Along with that, the terms used in woodworking to describe angled cuts don't make the origin of the angle measurement perfectly clear. The result is often some confusion about what it means to cut a piece of wood at a certain angle. Fortunately, the confusion is easily clarified by looking at a couple of woodworking terms that refer to angled cuts ("miter" and "bevel") and at how the two saw scales are set up the measure angles.

Miter Gauges, Miter Saws and Miter Cuts

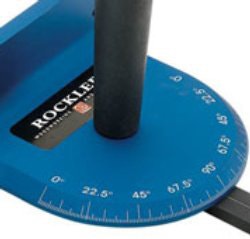

The term "square cut" means to cut a board at a 90 degree angle relative to one of it's edges. The term "miter" - when it's used describe an angled cut - implies a comparison to a square cut. To make a miter cut means to make an other-than-square cut in a material in preparation for making a miter joint. In keeping with that, miter cuts are measured with respect to a square cut. Making a 22-1/2 degree miter cut, for example, means making a cut at 22-1/2 degrees in one direction or the other from square across the board. You may have noticed that most power miter saws are adapted to this terminology. Most miter saw angle scales are set up so that the saw will make a square cut when the saw's angle scale is set at 0 degrees. One way to look at this is that the miter saw's scale is set up to measure the"amount of miter" that's being cut, and that setting the saw to cut 90 degrees straight across a board is, essentially, setting it to cut a "0 degree miter."

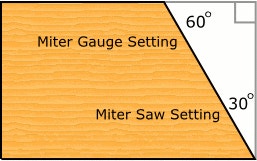

Table saw miter gauges, on the other hand, are typically calibrated to produce a square cut when they are set at 90 degrees. What the table saw miter gauge measures, in other words, is the angle of difference between the front edge of the miter gauge and plane of the saw blade. To get the same cut that a miter saw set at 30 degrees would produce, you'd have to set a typical miter gauge at 60 degrees.

A 30 Degree Miter Cut Miter saw setting = 30° 90° - 30° = 60° Table saw miter gauge setting = 60° Switching between the two scales is very simple. As you probably remember from geometry class, the two acute (less than 90 degree angles) of every right triangle are complementary angles (add up to 90 degrees). Since the intersections of the edge of an angled cut and the reference lines of the two calibration systems form a right triangle, the setting that will produce identical cuts from one scale to the next are complementary angles.

Bevel Cuts

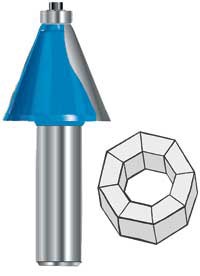

22-1/2 Degree Chamfer Bit Strictly speaking the term "bevel" can describe any angled cut, but it usually refers to a cut that's angled relative to face of a material. The angle of a bevel cut is almost always measured against a square edge-cut. A 22-1/2 degree bevel setting on a table saw positions the saw blade at a 22-1/2 degree angle relative to it's most upright position. Most angle-cutting router bits follow the same convention (except that they use term "chamfer" instead of "bevel" to describe the angled cut they make) - the cutting edge of a 22-1/2 degree chamfer bit tips inward from the surface of the router's base or the surface of a table router table at a 67-1/2 degree angle. Knowing the terminology and angle scale calibration conventions used in woodworking - along with a little common sense - is all it takes to get your tools set up to make the angled cuts you're after. Beginning on the next page, we'll take a look at some of the math that goes along with making angled cuts and building shapes with "odd angled" parts.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks