Wood Screw Glossary

Screws are the most versatile fastener in woodworking, but there are a lot of different choices. This glossary includes all the important terms you need to know related to woodworking screws. Understanding these terms will help you select the best screw for your project.

Shop Our Selection of Wood Screws

BoltA threaded fastener that threads into a corresponding nut or tapped hole. Bolts have machined male threads that match corresponding female threads. Smaller bolts used to install hardware like knobs and pulls are often called "machine screws" and have a combination Phillips/slotted head. |

|

ButtonScrew hole buttons are turned wooden plugs that are used to fill countersunk screw holes, concealing the exposed screw heads. Buttons are domed and left proud of the surface, as opposed to flat top plugs, which are trimmed and sanded flush with the surface. Also sometimes called "dome top" plugs. |

|

CapScrew caps are thin veneer discs used to cover exposed screw heads. The screws are countersunk flush with the surface, and the caps are adhered using the built-in peel-and-stick adhesive. Available in real wood veneers, as well as various melamine colors. Screw caps have the advantage of face grain matching (if made of real wood veneer) and simple installation, but won't be perfectly flush with the surface. |

|

Cap NutA type of T-shaped nut with a wide, low profile head. Used with Connector Bolts to assemble knock-down furniture. Cap nuts are functionally similar to T-nuts, but do not have prongs, and usually have an attractive finish. |

|

Connector BoltA bolt with a low-profile head, often with a decorative finish, that is used with a matching "cap nut" or cross-dowel to assemble knock-down furniture, and to connect cabinets or modular furniture components together. |

|

CounterboreA hole drilled so that the screw sits well below the surrounding surface, usually with the intention of filling the hole with a plug, or with putty. The counterbore hole diameter should precisely match the plugs you intend to use. |

|

CountersinkA funnel-shaped hole that allows a flat-head screw to sit flush with the surrounding surface. Also refers to the cone-shaped drill bit used to create the hole. Countersink bits are available for the countersink section only, or combined with a pilot bit. |

|

Decorative ScrewRefers to screws made from solid brass, or another metal with a "show finish," which will be fully or partially exposed once installed. Often offered in various finishes to match your hardware. |

|

Dome Top PlugTurned wooden plugs that are used to fill countersunk screw holes, concealing the exposed screw heads. Dome-top plugs are left proud of the surface, as opposed to flat top plugs, which are trimmed and sanded flush with the surface. Also sometimes called "buttons." |

|

Dowel ScrewA headless, double-ended screw with coarse wood threads on both ends. Dowel screws are used for concealed wood-to-wood connections, such as for baluster/rail connections. Similar to a "hanger bolt," but hanger bolts have machine threads on one end, and are more suited for knock-down applications. |

|

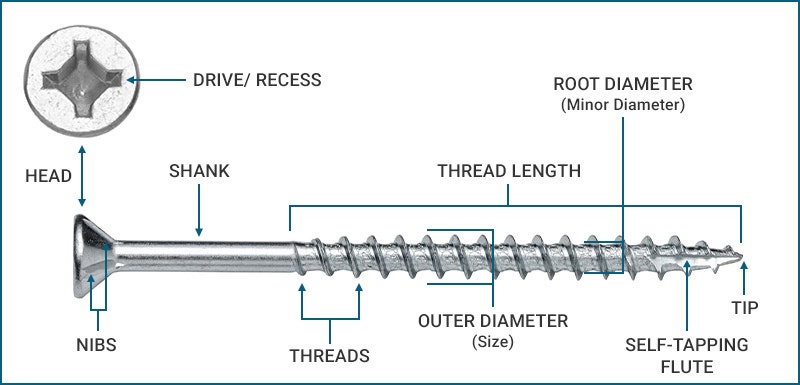

Drive TypeRefers to the type of screwdriver or driver bit used to tighten the screw. Examples includes Square drive, Phillips head, Star drive, Square-X drive and more. Also called a "recess," referring to the shape of the recess in the head of the screw. |

|

Exterior ScrewScrews specifically designed to withstand the elements and resist corrosion. Exterior screws may be made of corrosion-resistant materials, like stainless steel, or feature corrosion-resistant coatings. Not all coatings are exterior grade, so be sure your coated screws are labelled for exterior use. |

|

Euro ScrewA short screw with a thick shaft and coarse thread, used in the European 32mm system for installing hinges and drawer slides into 5mm diameter holes. |

|

Face Grain PlugsUsed to conceal exposed screw heads wherever a superior grain match is desired. Face grain plugs are cut with a special plug cutter that extracts a core from the face side of the board. Whereas a typical plug cut from dowel stock would leave darker exposed end grain, face grain plugs provide a better grain match and uniform stain absorption. |  |

Flat Head ScrewA screw head with a bugle shape and a flat top that is countersunk flush with, or below, the surface of the stock. Note that sometimes this term is used, incorrectly, to refer to a slotted screw. |

|

Flat Top PlugTurned wooden plugs that are used to fill countersunk screw holes, concealing the exposed screw heads. Flat-top plugs are trimmed and sanded flush with the surface, as opposed to dome-top plugs, which are left proud of the surface. |

|

Hanger BoltA headless bolt with two threaded tips: one pointed, with coarse wood screw threads, and the other blunt, with machine screw threads that accept a threaded nut. Often used in knock-down applications, or to attach metal components, or components that may be removed later, to a wooden sub-structure. |

|

Hardware Mounting ScrewRefers generally to the small screws used to attach hinges, knobs, drawer pulls and drawer slides. Typically included with the hardware item, often in a matching finish. |

|

Head TypeRefers to the overall shape of the screw head (not to be confused with "drive type"). Different head types are available for both functional and cosmetic purposes. For example, a washer-head screw offers a wide bearing surface for strength, while a trim-head screw offers a very small hole to fill in finished woodwork. |

|

Knock-Down FittingHardware that is used to assemble anything that will require disassembly later on, either because the item is very large, or it will be frequently moved. A common example in the wood shop are the bolts and cross dowels used to assemble the trestle of a woodworking bench. |

|

Lube FinishA low-friction finish on wood screws that allows the screws to sink in quickly with less effort. What woodworkers used to achieve using soap, a lube finish achieves without the mess. |

|

Machine ScrewA type of bolt, typically small in size, that is used to install hardware items like knobs and pulls. Often has a combination Phillips/slotted head for ease of installation by the end user. |

|

Oval Top PlugAnother term for "dome-top plugs," which are turned wooden plugs used to fill countersunk screw holes. Oval-top plugs are left proud of the surface, as opposed to flat top plugs, which are trimmed and sanded flush with the surface. |

|

Pan HeadA screw head with a thick dome or puck shape, with a flat bearing surface under the head. Often used for attaching drawer slides, hinges and other hardware items. The flat bearing surface prevents over-driving when using for wooden parts. The head profile is comparatively high, which forms a deep recess for the driver bit. |

|

Pilot HoleA pre-drilled hole that accepts the threaded portion of a screw. Pilot holes help to prevent the wood from splitting, and ease the driving of the screw. The pilot hole should be smaller than the outer diameter of the screw threads, but no smaller than the root diameter (the thinnest part of the threaded section). |

|

MDF/Particle Board Screw (Confirmat Screw)A type of screw with deep, coarse threads and a thick shank, designed to provide a secure hold in particleboard and MDF. The thicker shank means more total thread length in the wood. This, combined with the deeper thread biting into the wood, helps prevent pull-out. |

|

Phillips DriveA common drive type consisting of a simple X-shaped recess that tapers to a point. Phillips head screws provide a positive fit that won't slip out of the screw head like a slotted bit. However, they are designed to "cam out" once tightened past a certain point, in order to provide some protection against breaking or stripping the screw. |

|

PlugA round wooden plug used to fill countersunk screw holes, in order to conceal the screw head. Available in two basic shapes: flat top, which are trimmed and sanded flush, or dome top (also called oval top or buttons), which are left proud. Depending on availability, each shape may be offered in either end grain plugs, which provide a contrasting darker end grain, or face grain plugs, which blend better with surrounding face grain surfaces. Also see Pocket Hole Plugs. |

|

Pocket Hole ScrewScrews designed specifically for pocket hole joinery. Pocket hole screws, or "pocket screws," fit into steeply angled countersunk holes to join pieces together with no unsightly holes on the opposite face. The screws feature a flat bearing surface that helps prevent splitting and overdriving, and are available in a range of lengths and thread types to suit your material. |

|

Pocket Hole PlugWooden plugs designed specifically to fill the elongated angled holes left by pocket hole screws. |

|

Pozi Drive/PozidrivA drive type that is often mistaken for a Phillips drive, but is actually quite different. Superficially, the Pozi Drive recess looks like a Phillips recess, with smaller slots radiating from the center of the cross. However, the shape is carefully engineered to prevent the cam-out that was originally an intentional design feature of the Phillips head screw. |

|

Pyramid Top PlugSquare wooden plugs with a neatly cut pyramidal top that are used to fill countersunk screw holes. Often used as decorative accents in Craftsman style, Mission style, or Arts and Crafts style furniture and cabinetry. |

|

Rockler Insty Drive Drill/Drive SystemA quick-change drilling and driving system that lets you drill a pilot-hole and countersink with one plunge, then slide a driver bit sleeve over the top for driving the screw. The complete system also accepts self-centering bits, which are great for installing hardware. Click Here to shop all Rockler Insty Drive Products. |

|

Round HeadA screw head with a prominent half-dome shape. Sometimes used for decorative effect, the domed head also provides a secure recess for the driver bit and a flat bearing surface. |

|

Slotted DriveA traditional drive type with a simple slotted recess, used mostly for period furniture, where a more modern drive type would seem out of place. |

|

Star DriveA 6-pointed star-shaped recess that offers excellent resistance to cam-out. Often referred to by the trade name "Torx." Star drive bits come in a range of sizes and are labelled, for example, T-10, T-15, T-20 etc. |

|

Square DriveA drive type with a square recess in the head. The recess is tapered, providing a secure wedge-like fit with the driver bit, and very little cam-out. Often called Robertson drive, after its inventor. |

|

Square-X DriveA specially-shaped hybrid recess that can be driven with either a Phillips bit or a square drive bit. Offers the secure fit and durability of square drive, with the easy, customer serviceability of a Phillips drive screw. |

|

Threaded InsertA threaded metal fastener that is used to add machine threads to a wooden board, in order to accept a bolt or machine screw. Threaded inserts have coarse wood threads on the outside and finer machine threads on the inside. They are designed to thread into a specific hole diameter - be sure to check the Technical Documents before installation. |

|

T-NutA T-shaped metal fastener with a shank that houses female threads, and a bearing surface with sharp prongs that bite into the surrounding wood to prevent rotation. Used to add machine threads to a wooden board, in order to accept a bolt or machine screw. |

|

Trim HeadA small screw head that can be sunk below the surface and easily filled with putty. Trim head screws are the screw equivalent of a finish nail. They are often used in trim carpentry where you need the holding power of a screw, but an unobtrusive head that won't damage the surrounding surface. |

|

Truss HeadA screw head with a low-profile, dome-shape and a flat bearing surface. Truss head screws are similar to pan head screws, but have a lower profile and slightly larger bearing surface. The lower profile is sometimes necessary for drawer slides where clearance is needed between the various members. The low profile also means a shallower recess, making the screw more prone to cam-out. |

|

WasherWashers are used to add bearing surface beneath the screw head. The added bearing surface is useful when you need more holding power (by preventing pull-through) or a means of adjustment, either by feeding the screw through an overly large hole, or an elongated slot. Washers are available with countersunk holes, which effectively convert a flat head screw into a washer head screw. |

|

Washer HeadA screw head with a built-in washer that enlarges the bearing surface of the screw. Used for more holding power or to prevent the head from penetrating into the material under torque. Often used in slots when adjustment is needed, or to accommodate for the expansion and contraction of a wooden top. |

|

Wood ScrewA screw with a sharp point and a comparatively coarse thread designed to bite into the wood for a secure hold. Wood screws are available with a variety of head types (shape of head), drive types (shape of driver bit), lengths, thicknesses, materials and finishes. Traditional wood screws sometimes have a thicker section of unthreaded shank below the head, and require a separate pilot hole for the shank. More modern screws generally have the same root diameter all the way to the head, and can include a number of convenience features, such as nibs (ridges) under the head that allow the screw to countersink itself. |

|

Shop Our Selection of Wood Screws

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks