Wood Screw Buying Guide

Wood screws are available in a huge variety of types, making them incredibly versatile, but also a little confusing.

This guide will help you sort out the differences so you can choose the right screw for the job, whether you're fastening deck boards or hinges, or joining face frames or casework. To make it easy to follow, we'll start with the basics and work our way down to the nitty-gritty details.

The Basics

How Long is Long Enough?

First things first—choosing the right length. If the underlying material is very thick and drill-through is not a concern, a good rule of thumb is that at least 2/3 of the screw should end up in the underlying piece for sufficient holding power. If drill-through is a concern (the underlying material is thinner), then your screw should pass through the first layer and come within no more than 1/8'' of the far side of the underlying material. If you get any closer, the tip can create a small raised bump that you likely won't see until the finish is on your project.

Shop by Screw Length.

|

Screw TipTo ensure that the screw pulls the two parts together snugly, drill a ''clearance hole'' in the the piece you are fastening. The clearance hole should be a bit wider than the widest part of the screw shank. This will prevent the threads from biting into the top piece and pushing the two parts away from each other. |

What About Screw Size?

This refers to the thickness of the screw shank, and is designated with a # sign followed by a number. You should scale your screws to the job at hand—the larger the number, the thicker the shank of the screw, and the more load it can support. Generally, #0 through #5 screws are smaller and used for delicate projects and hardware installation. Screws from #6 through #10 are used for general-purpose joining of panels, and are also popular sizes for pocket hole screws. Thicker screws such as #14 screws are used for decking, construction and cabinet installation.

Shop by Screw Size.

Will Your Screws be Visible or Hidden?

If your screws are used to attach hinges and other hardware, then they'll be at least partially exposed, and should match the hardware whenever possible. For this reason, we offer screws in zinc, nickel, polished or bright brass, antique brass, statuary bronze and more. For screws that will be hidden, finish is less important, but we do offer a low-friction "Lube" finish, which makes it easier to sink long screws.

Click here to shop our Decorative Screws, available in many cosmetic finishes.

Will Your Screws be Used Outside?

If your project will be exposed to the elements, you'll need screws that are specifically labelled for exterior use. We offer screws with finishes such as Blue-Kote and Exterior Bronze Ceramic that are designed to hold up to rain and humidity. For the ultimate in rust protection, we also offer solid stainless steel screws.

What Material Are You Screwing Into?

Some screws are optimized for specific materials. Examples include our Confirmat screws, which are designed for strong joints in particleboard. We also offer Powerhead screws, which help prevent melamine materials from chipping around the screw head. Pocket hole screws are often offered in your choice of coarse threads, which are better for softwoods, and fine threads which are better for hardwoods.

|

Screw TipNever use a drywall screw in wood. Drywall screws are made from hardened steel that is brittle and prone to breakage. Wood screws are less brittle, and have more metal around the shank, giving them far greater strength under torque. |

A Note on Solid Brass Screws:

Most screws are made of carbon steel, but solid brass is the traditional choice for reproductions, restorations and high-end furniture. Be aware, however, that solid brass is soft, prone to breakage, and always requires a pre-drilled pilot hole. For this reason, some woodworkers opt for steel screws with a plated finish.

Special Purpose Screws:

Very often, screws are sold for a specific purpose, which makes them easy to find. Purpose-built screws include Pocket Hole Screws, used for assembling frames and casework, Decorative Screws, with finishes to match your project, and Drawer Front Screws, which allow you to adjust false drawer fronts.

The Nitty Gritty

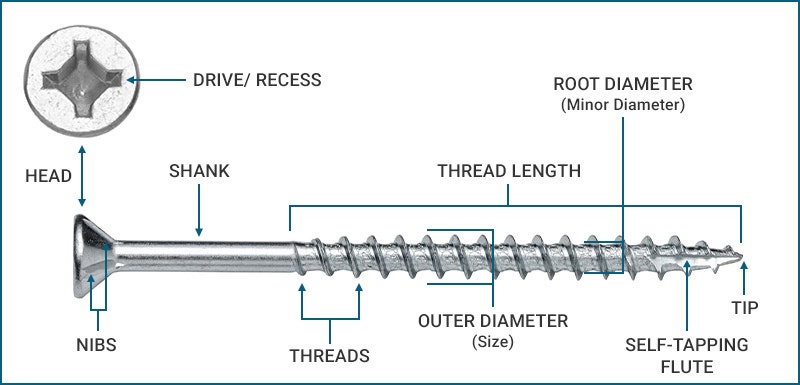

Now it's time to drill down to the details. Every screw is made up of the same basic parts: a head with a recess for the driver bit, a threaded shaft and a tip. Each of these parts can have different features for different applications. Let's go through them from head to toe.

What is "Head Type" and Which Should You Choose?

Head Type refers to the overall shape of the screw head. If you want the screw to be flush with the surrounding surface, a Flat Head Screw is your go-to choice. Some flat head screws also feature "nibs," ridges under the head that mill out the wood, allowing the screw to countersink itself. If you need more holding power and resistance to racking, the flat bearing surface of Pan Head Screws will provide it. If the screw will slide in a slot for adjustment purposes, consider Truss Head Screws and Washer Head Screws, both of which offer a flat bearing surface and a wider head that works well in adjustment slots.

Two additional head types are commonly used for cosmetic purposes. Round Head Screws have a prominent half-dome head that is sometimes used for decorative effect, and Trim Head Screws feature a small head that is easily sunk below the surface, and the hole filled with putty. These are often used in trim carpentry applications.

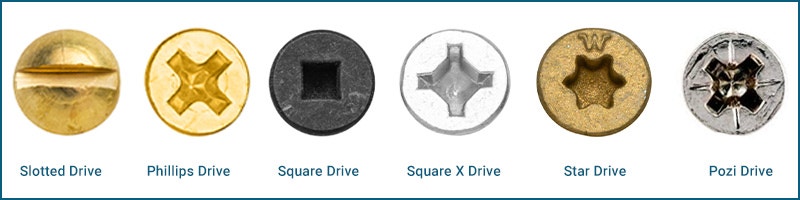

What is "Drive Type/Recess" and Which is Best?

Drive Type indicates what type of screwdriver or driver bit you use to install the screw. Options now include much more than just Slotted or Phillips drive. Drive types like Square, Square-X, Pozi and Star offer enhanced performance that make cam-out and stripping a thing of the past. Square-X Drive is a newer hybrid recess that can be driven with either a Phillips bit or a square drive bit. This means you get the durability of square drive, with the customer serviceability of Phillips drive.

|

Screw TipIf you own a cordless drill, be sure to use the clutch on the drill to protect against breakage and stripping. Using the clutch also lets you select a screw recess with less cam-out, further reducing the risk of stripping the head. |

Shank/Thread Considerations:

The shaft of the screw can be fully or partially threaded. Longer screws are often unthreaded below the head; the additional metal here makes them stronger and helps disperse heat. Threads can be coarsely spaced for soft woods or for fast driving, or they can be finely spaced, which some prefer for harder woods, or for slower driving. Some of our screws feature threads with tiny serrations for easier driving, more holding power and less risk of splitting. Search for serrated threads or WoodMaster™ threads to find these screws.

|

Screw TipTraditional wood screws (this includes most solid brass screws) have a thick shank that is as wide, or wider, than the threads. This thick shank helps prevent the soft brass from breaking under torque. Be sure to drill a separate pilot hole to accommodate the shank. |

Tip/Point Considerations:

Take a look at the tip of the screw. If it has a flute cut into it, that's no accident. This fluted-tip acts like a drill bit, boring out material as the screw winds its way into the wood. Often, this eliminates the need to drill a pilot hole. A high-quality screw will also have threads that go all the way to the very point. This makes it easy to start the screw, with less wobbling. We're proud to say that all of our Centerline screws bring the thread as far to the tip as possible, for the easiest driving.

And that about nails down the differences between our various screws! Don't forget that we have expert staff in our stores, online and available by phone to help out if you have a question that's not answered here.

Click here to shop all Wood Screws .

See Our Wood Screw Glossary

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks