Why Is It Important To Apply Shellac Before Stain?

Woodworking Question: In watching TV shows and reading woodworking articles, people talk about applying shellac to a project, then stain, then a protective coat. Why the shellac before the stain? Here's what our experts had to say.

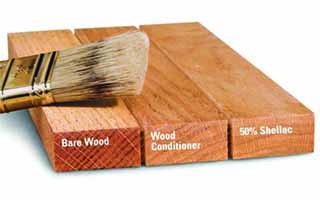

Answer From The Experts: Some woods, notably softwoods, tend to absorb more stain than people would like, often selectively, such as in the early wood bands as opposed to the late wood bands. Other woods, like cherry, tend to blotch under oil-based stains. Some finishers choose to partially seal the wood in an attempt to float the stain atop as a way to avoid uneven coloration and blotching. One way to do that is to use very dilute dewaxed shellac as a sealer.

However, I am not a fan of this method for a number of reasons. It does not work in all situations, it is far from foolproof, and it is frightfully easy to make things a whole lot worse. Along with using only dewaxed and not regular shellac, the method demands that you know exactly how much to thin it, how quickly to wipe it off and when you need to sand afterwards. These things vary with the wood and stain in question. In other words, it is one of those methods that people spend time perfecting and manage to make work with their particular stain products and regimens. It is far from foolproof and therefore is not what I would recommend as a general practice for those who have not practiced it beforehand on scrap with their particular chosen wood and stain.

Another Option: Wood Conditioner

There is, however, a far easier alternative offered by the same companies who make the affected stains. Companies selling oil-based stains, the ones most prone to blotching, also sell wood conditioner. You flood it on, wipe it all off, then stain while the wood is still wet using the same method: flood the stain on and wipe off all that is not absorbed. You end up with both a safe and uniform alternative, with no risk of layering too much stain or the wrong type of stain atop sealed wood, a situation that can cause not only muddiness but also delamination.

Simply put, wood conditioner is a far less risky alternative, and the companies themselves clue you in to which types of stains may need it by marketing it together with those particular stains. All you need to do is figure out which woods are likely to benefit, and I can tell you that: softwoods, cherry, very absorbent woods like poplar, and in some cases, woods with unattractive twisted grain, such as soft maple. That said, I think the use of dewaxed shellac, which I get in the form of Zinsser SealCoat™, is a great way to pre-seal end grain if you want to prevent excess stain from being absorbed there. While wood conditioner helps in that situation, it is often not adequate. By flooding SealCoat only onto the end grain, then wiping off what does not absorb and later sanding lightly, you end up with end grain that takes stain about the same as the flat grain.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks