Video: Installing SOSS Hinges with Hand Tools

Michael Alm demonstrates the installation of SOSS invisible hinges including how to make a template, cut the mortises and get great results without a plunge router.

You can find more great projects and techniques from Michael Alm at his website.

Featured Tools:

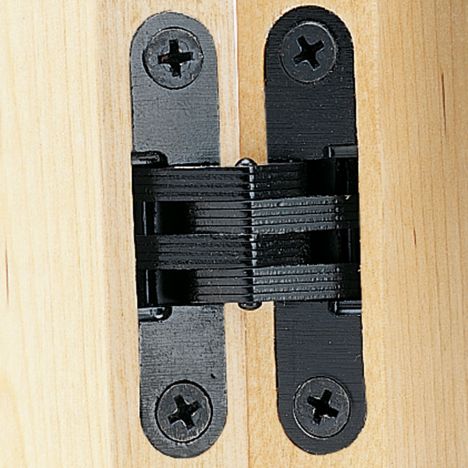

Michael Alm: Hey, everyone, Michael Alm here. This week I'm working on this bench build and I need to install some SOSS hinges into these two doors. This is a SOSS hinge, and they're called a concealed invisible hinge because, when they close, you can't see them at all. They're super sleek, takes your furniture building up to the next level, and the cool thing about them is that they're not that expensive and they're not that hard to install. I'm going to take you through step by step how I install them. I install them with very limited tools, just a drill bit and a chisel. It's something you can totally do, so stick around and I'll show you how.

Your SOSS hinges will come with an instruction guide, and inside of that instruction guide will be a bunch of paper templates. These are for all the different sizes and shapes that they make. All you have to do is find the one that is right for you. I like to make a more permanent template than using the paper template every single time because it just breaks down after three or four uses. You can see I'm just using a couple of scrap pieces of wood that I have in my shop, just using the CA glue as a clamp and the wood glue as a permanent bond because I do plan on using this multiple times in my shop. Spray it down with the accelerator and then I can clean up the excess glue.

As I mentioned before, there are a whole bunch of different templates inside of the instruction manual for the SOSS hinges. I selected mine, which are the 101, but the process is going to be the same between all the different types of SOSS hinges. Trim that out and set it against the fence of my wood template. Then I can tape that down into place so it doesn't move. You can use a scratch-all, or I have an ice pick here to mark all the different placements. Make sure that you get this right and perfectly in the right spot, this is pretty essential.

Once I had those marked, I could remove the paper template and then prepare to drill the guide holes. I'm using a 3/8-inch drill pit on this, it's what's specified in the instructions, and I just drill those all the way through. If you don't have a drill press, it's not that big of a deal. You could drill these by hand. You're drilling from the inside, which is nice, so that means that where the drill bit comes out is going to be in the precise location.

One thing that I realized that I forgot to do when I was making the jig was, I didn't mark my center line. This is very important for the alignment on the cabinet. I just went up to my garage door, had a lot of light shining through and I marked that center line. Now I want to transfer that center line around the front edge of it. I just used a 1-2-3 block to do that. I know this is nice and square. If you don't have one of these, I'll put a link down in the description below. They come in surprising handy for multiple projects.

Now I'm establishing the center line of the hinges on the actual door. This is somewhat arbitrary. There are suggestions in the instructions of where to place it. It depends on your door, and with a lightweight door like this, it doesn't really matter too much. Now that I have the marks on the door, I can set the marks on the cabinet. You'll notice that this door is just set to fit. I cut this out so that it's a snug fit all the way around, and then I'm going to trim the door again later. I'll show you that in a little bit.

Now you can see those marks line up with the jig and it's easy to see, for me, I probably should have done it on ink for video, but I can see that really well. Then now, all I have to do is set the depth. In order to do that, the instruction manual definitely has some suggestions for the depth. I just like to do it the old-fashioned way and mark it directly from the hinge, that way I know exactly where I'm going. Then I need to set the depth on my drill bit. The simplest way to do this is with blue tape. They make stop collars and all sorts of other things, but this works just fine. I've been using this technique for years, and it's honestly pretty precise.

One of the things that I will suggest, that if you are going to do this a lot, is that you purchase a second Forstner bit. I happen to have one in my shop and I was really thankful for that because the two inside holes are deeper than the two outside holes. If you only had one Forstner bit, you'd be constantly trying to switch back and forth, or you might have to drill out all the holes for one of them and then switch over to the other one. Anyway, it would be a pain, so it's definitely a good idea to invest in a second Forstner bit.

Now I'm just setting the jig into place with that line that I made before. Once it's firmly in place, I can start drilling. I just started with the outside holes. You just watch for that tape right when it touches down, that's when you want to stop. Now it's really important to be precise with the two outside holes, but when it comes to the two inside holes, it's not really as essential. You just don't want the center of the hinge to end up bottoming out. I actually ended up going a little bit deeper than the tape on these inside holes, and you just want to be cautious when you're going through a three-quarter inch cabinet side that you don't accidentally drill all the way through.

The next step is to start trimming out the mortises, and I like to start that by making a line between the four different holes. Once that's established, I can start moving into chiseling, the line just establishes where the chisel is going to stop, but I start from the center and then work my way out. I like to do this because it doesn't put too much pressure on that line. As you break away material, the line will stay and the material has some place to go. If you start by just chiseling right into that line, there's a good chance you'll break out the side of it, which is the path of least resistance.

The middle section is the hardest one to chisel out, I found that doing an x pattern was a really good way to cut through that grain, but just take your time on this and make sure you get it nice and precise.

I managed to nail the depth on the first try, but there were definitely ones where I needed to drill out a little bit more. Since you already have those holes established, you can very easily go back with your Forstner bit and drill it out just a little bit deeper. Now I can move on to the cabinet sides. This is basically a rinse and repeat, same deal as before, a little different clamping method. I removed the top of this cabinet just so that you guys can see, and just drill through, making sure not to drill all the way through the cabinet side, that would be a real bummer. Then you can remove the template and start chiseling it out.

The plywood actually cuts even easier than the solid wood, so this really didn't take very long. With the mortises all cleaned up on both the cabinet side and the door, it's time to dry fit the hinges. With the hinges in place, I need to drill out those holes. For that I like to use a Vix bit or also known as a self-centering drill bit. I get these from Rockler. I bought a whole set so that I have all the different size screws that I need. I'll put a link down in the description below where you can pick one up yourself. Then the self-centering bit you just drilled down in, if you don't have one, you can certainly do this with a regular bit, but it definitely makes things a lot more precise.

As I mentioned earlier in the video, this door is a snug fit. That's intentional because I like to get the hinges in place and then figure out all of the reveals and everything, just in case something is off. What I do is, I trim trace it out from the inside, and then from the outside I establish all of the different offsets that I need. In this case, it was 360 forts, which was the same offset on the inside of that hinge.

I used my track saw to trim it up. You could definitely use a circular saw for this, but I recommend using some sort of fence. The last step in the process is to just put the door back in place, put the screws back in and double-check your reveal. There it is, that is how to install SOSS hinges using basically just hand tools. It's not that hard. It's a little bit time consuming, but by the time I'd done a couple of them, it was only taking me about five minutes a piece, which, I think, is totally doable. There's certain applications like this where you can't fit a router inside of the cabinet.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks