Understanding T-Nuts and Threaded Inserts

Threaded inserts can come in handy for certain assembly tasks. T-nuts — a variation of threaded inserts — are another niche piece of hardware that add a helpful arrow to your woodworking quiver.

Threaded inserts and T-nuts provide a way to use bolts or other threaded hardware to attach things like legs, headboards or backsplashes to furniture quickly and easily, with the added benefit that the pieces can be taken apart — or knocked down — with very little fuss.

While it may seem as if the uses for this sort of joint would be limited, it is surprising how often they come in handy. And sometimes they are the only solution.

It may appear that inserts and T-nuts are essentially the same in function: they provide a threaded "nut" embedded into wood or some other substrate. The main differences are in how easy they are to mount and how strongly they hold. Understanding those details will help you decide which insert is right for you.

Mounting the Hardware

This may seem backwards, but let's talk first about how to install threaded inserts and T-nuts as our starting place.

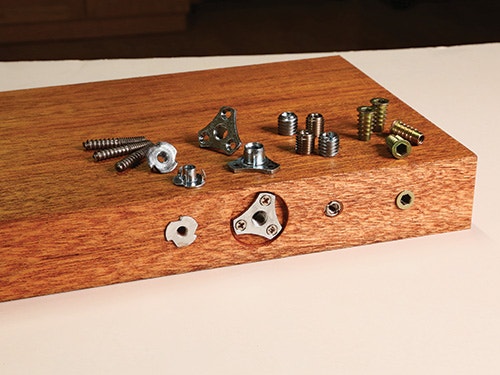

First thing you need to do is drill a hole ... or maybe two. For the barrel-shaped inserts, one hole will do. They will thread into place flush to the surface of the workpiece. For T-nuts, screw-on T-nuts and tapered/flanged threaded inserts, you need to make a decision. They will sit proud of the surface without also pre-drilling a recess for their flanged portion. See the image above for clarification; the flanged insert and the standard T-nut both are sitting slightly proud of the edge of the board. If you want whatever you are screwing into or attaching to your hardware to be tight to the surface, you need to accommodate those details.

There are also considerations regarding the hole size that you bore as the primary mounting hole. Each piece of hardware will have a specified drill bit size, most often found on their packaging. I've sometimes gone with a slightly smaller-diameter hole, especially in softer woods (basswood vs. hickory as an example). It can make installation a bit harder but provides better holding performance.

For actual softwoods, the threaded insert of choice is the tapered/flanged insert. An important point to keep in mind is that you select your insert or T-nut by the thread on the inside of the hardware — be it 1/4-20 for a 1/4" bolt or 5/16-18 (5/16" bolt) or 3/8-16 (3/8") and so on. Metric sizes are no different.

Installing standard T-nuts is easy: drill the pilot hole and hammer it home. Screwed-on T-nuts are also easy. Bore the correctly-sized hole (and flange recess if you choose), tap the T-nut in place and then pre-drill and drive in the three screws. The other inserts are a bit tricker.

A common way to drive barrel-shaped inserts into a prebored hole is with a bolt properly threaded for the insert. Add a few nuts to the bolt so that just a small amount of thread is exposed. Screw the threaded insert onto the bolt and use a ratchet to turn the insert into the hole. You might notice a screwdriver slot on the top edge of the insert. But trying to drive in an insert with a screwdriver is asking for trouble. The slot is better suited for taking an insert out.

If you have a lot of inserts to drive in, consider chucking a threaded rod into your drill/driver and put a nut on it. Then put the insert on the threaded rod and get busy.

If you are having trouble getting your inserts to start square to the surface of your wood, use a similar setup in your drill press ... but DON'T turn the drill press on. Use your hand to turn the chuck and thread the insert home.

The tapered/flanged threaded inserts are best used in softwood, and many have a hex-drive socket built into the insert. Use an Allen wrench to drive it in.

Which Insert to Use?

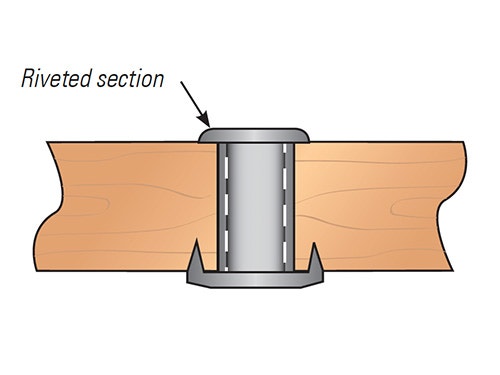

This is the most important question for choosing one of these pieces of hardware. For me, it comes down to how strong the joint needs to be. Classic T-nuts, while quick and easy to install, do not perform well when tension is applied (when you pull on the joint). Strong in shear and under compression, as all of these inserts are, their ability to withstand tension varies considerably. A well-installed barrel-shaped insert will provide the most strength under tension. The screwed-in T-nut is second-most strong, the tapered/flanged is next and the classic T-nut is the weakest. The chart spells this out. The riveted T-nut is also quite tenacious under tension, but it is the fussiest to install. Choose your product with those constraints in mind.

Threaded inserts and T-nuts are versatile and can solve a bunch of woodworking problems. Attaching removable panels, mounting legs with hanger bolts hanging shelves, creating knock-down projects — the limit is your imagination. Simple in concept and eff ective in use, why not give these fasteners a try in your shop soon!

Relative Strength

| T-nuts | Screw-on T-nuts | Barrel-shaped Threaded Inserts | Flanged Threaded Inserts | |

| Shear |

Strong |

Strong |

Strong |

Strong |

| Tension |

Weak |

Moderate |

Strong |

Strong |

| Compression |

Strong |

Strong |

Strong |

Strong |

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks