Understanding Planers and Jointers

Properly preparing lumber is a key to successful woodworking. These two tools are essential to that surfacing process.

Mortises and tenons, socks and shoes, soup and sandwiches, chewing gum and school desks ... some things just go together. When it comes to properly preparing wood, a jointer and a planer are just such a dynamic duo.

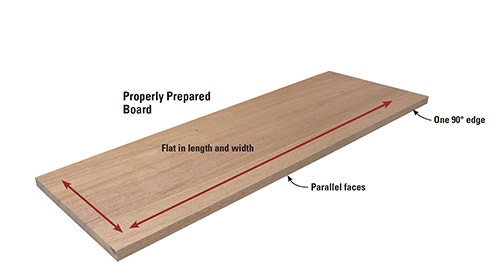

The inconvenient fact that trees grow with round trunks, and we must extract rectilinear boards from them, is why proper stock preparation is so important. What is "properly" prepared stock? Well, the ideal piece of wood has two surfaces that are flat in length and width. Those faces should be parallel with one other, and there should be a least one edge that is exactly 90 degrees to the faces. In addition, the board needs to be surfaced to the thickness required for your specific task at hand. Working in tandem, jointers and planers allow you to create properly prepared lumber in much less time than it would take to prepare it the same way with hand tools.

What They Do

Although they have similar cutterheads, jointers and planers perform completely different jobs that are integral to stock preparation.

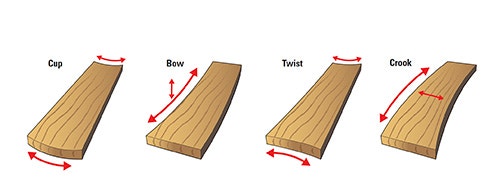

Jointers flatten wood. They have long infeed and outfeed tables. The top edges of their rotary cutterhead are perfectly flush with the top of the outfeed table. By lowering the infeed table, you can remove a small amount of material as you pass the wood over the cutterhead from the infeed to outfeed side. While rough lumber from a mill, or even wood you buy already smooth, will be more or less flat and straight, a jointer is essential for making any board absolutely flat across its width and along its length.

Jointers have a vertical fence mounted beside the tables that helps you guide stock safely across the cutterhead. It's also essential in squaring one edge of a board to a surfaced face.

Planers surface wood to make it thinner. Powered rollers feed the wood through the machine and past a cutterhead that removes material from one face in exact amounts. They do not make distorted lumber flat. If you put a bowed board through a planer without flattening one face first, you will still have a bowed but thinner board exiting the machine.

Once one face of board has been jointed flat, it can be surfaced in a planer to create a second flat face, parallel to the first, and be reduced in thickness. Then when the second edge is cut square to the first and jointed smooth, it can be glued to other board edges to create wider panels.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks