Tips for Buying Table Saw Blades

What size blade does your saw require? Most table saws use 10" blades, but some take smaller blades, and some take larger. Though not generally recommended, you can use a smaller blade than your saw is designed to handle (with the obvious loss in depth of cut). Never try to use a larger blade.

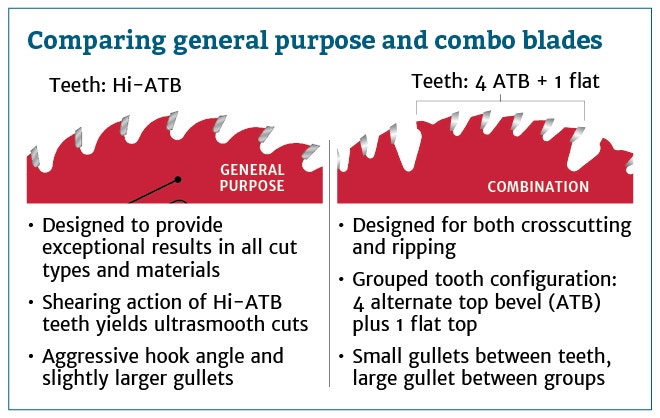

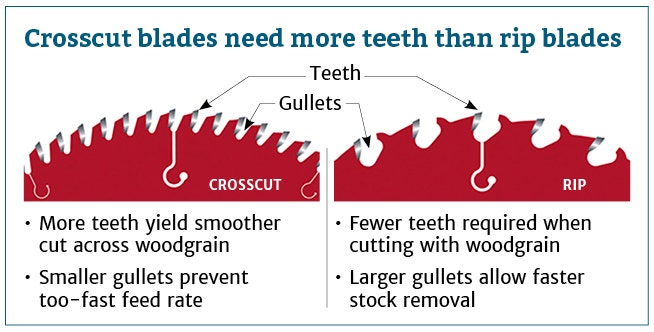

What kind of cuts will the blade need to make? Primarily rip cuts (with the grain) or crosscuts (across the grain)? Because it's easier to remove material with the grain, ripping blades typically have fewer teeth, and they're set at a more aggressive hook angle and separated by larger gullets to cut and clear wood chips as quickly as possible. The teeth themselves are flat-topped or shaped with triple-chip-grind geometry, both of which are well-suited to cutting with the grain. Because it's harder to get a clean edge when cutting across the grain, crosscut blades have more teeth, which generally are set at a slightly less aggressive hook angle and feature a knife-like alternating-top-bevel geometry that allows them to slice across the wood's fibers. If you're working in a shop with table saws dedicated to each type of cutting operation (or if you don't mind switching out blades on a single saw), specialized blades might be the right choice for you.

But if you need the blade to handle both types of cut with more or less equal frequency and you don't want to have to switch the blades each time (or buy two blades to begin with), you'll want to check out a combination or general purpose blade. These blades balance the number of teeth, hook angle and tooth shape to give you the best results in a variety of cuts. Freud's Premier Fusion general purpose blades, for example, promise excellent results in all kinds of cuts.

What kinds of material will the blade need to cut? Some manufacturers have developed blades designed specifically for certain materials that are prone to splintering or chipping when cut with a regular blade. Freud, for example, offers blades designed to deliver excellent cuts in plywood and melamine- and laminate-coated materials. These blades feature a high tooth count, less aggressive hook angles and tooth shapes that score the material to avoid chip-out. If you cut a lot of these materials, a specialty blade might be a good idea for you.

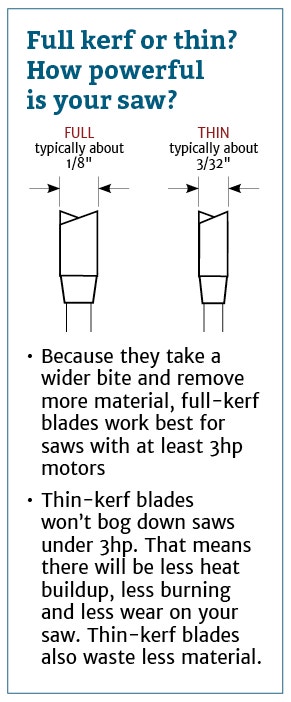

Finally, how powerful is your saw? Many blades are available in full-kerf and thin-kerf varieties. Although they can be used in any table saw, thin-kerf blades were developed specifically for use on portable and contractor-style table saws with 1-1/2hp or smaller motors. These saws can bog down with full-kerf blades, resulting in heat buildup and decreased cut quality. Thin-kerf blades are narrower and remove less material, and, as a result, they require less power. So if your saw's motor is less than 3hp – or you want your lumber to go as far as it possibly can – give thin-kerf blades a serious look.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks