Precision Miter Gauges and Crosscutting Sleds

Are you getting the most out of your table saw? If you're like many woodworkers, you use your table saw almost exclusively for ripping wood, and haven't really explored its potential as a crosscutting tool.

That's understandable - even the best saws don't often arrive from the manufacturer equipped for precision crosscutting. To perform well in that area, most require a crosscutting equipment upgrade to a precision miter gauge or miter sled. In this article, we'll look at what it takes to get good crosscuts on a table saw, and the precision crosscutting tools that can make the process easy, accurate and reliable.

Is a Table Saw the Right Tool for Crosscutting?

Sawing lumber can be divided into three basic operations: ripping, crosscutting and re-sawing. Crosscutting is cutting wood to length across the grain. Ripping refers to cutting lumber to width lengthwise, and "re-sawing" is the name given to sawing lumber to a specific thickness. In most small woodworking operations and hobbyist shops, ripping and crosscutting are by far the most common, and are among the most fundamental operations in woodworking.

A table saw is the obvious choice for ripping wood. A well equipped table saw makes fast efficient work of cutting lumber to width, and with a good blade and a reliable fence on your saw, you can expect a straight and smooth cut. A table saw isn't as often thought of as a crosscutting tool, however. In many shops, a radial arm saw or a compound miter saw does the heavy lifting in the crosscutting department. But even though these "dedicated" crosscutting tools make fast work of many crosscutting operations, it's a mistake to sell your table saw's crosscutting potential short and think of it as primarily a "ripping machine."

In many situations, a table saw is actually the crosscutting tool of choice, and sometimes it's the only tool for the job. When outfitted with a precision miter gauge and crosscutting sled, a table saw is the safest and most reliable tool for working with very small parts. It's also the the only machine that lets you perform a crosscutting operation on only a part of the workpiece, such as cutting notches, or the fingers of a box joint. A table saw has a greater angle cutting range than other crosscutting tools. Most radial arm saws and compound miter saws are limited to 45 degrees or a little more in their angle cutting capabilities; given the right equipment, a table saw can cut any angle between 0 and 90 degrees.

Getting Good Crosscuts on a Table Saw

Strangely enough, even top-of-the-line table saws rarely come equipped for crosscutting with anything more sophisticated than a standard T-square miter gauge. This type miter gauge is comprised of a miter bar (which rides in a corresponding miter slot in the surface of the saw) and a positionable protractor head. You set up for making angle cuts by aligning the angle scale on the protractor head with a cursor attached to the bar.

Unfortunately, a standard-issue T-square miter gauge is woefully inadequate to the task of making the precise crosscuts necessary for tight fitting, gap-free joinery and for a host of other common woodworking objectives. Problems with its design - including the lack of a reliable system for setting precise angles, inadequate support for the workpiece, and (often) a sloppy fit between the miter bar and miter slot - prevent it's usefulness for even the most routine 45 degree miter cuts for a simple four-sided frame.

The key to accurate table saw crosscutting is having equipment that lets you quickly and reliably cut a variety of stock sizes to accurate lengths and at accurate repeatable angles. Fortunately, a few after-market miter gauges and miter sleds that significantly enhance the crosscutting performance and versatility of the table saw have been developed. Below, we'll look at our top picks, and the features that make them solid investment.

What makes a Precision After-Market Miter Gauge Better?

Setting Accurate Angles

One of the main challenges in crosscutting on a power saw is setting up precise angles on a consistent basis. After-market universal miter gauges, like those made by Kreg as well as Incra Tools line of precision miter gauges are equipped with "positive stops" - a mechanical system that allows quick and precise setting of a range of angles.

The Kreg Precision Miter Gauge uses pins to set the positive stop settings and micro adjusts to 1/100th of a degree, a level of accuracy high enough for nearly anyone's standards.

While the Incra miter gauges operate on a slightly different system, with indexing teeth laser-cut into a solid steel protractor head in 5 degree increments, and a precision vernier scale for angle settings in finer increments. Both miter gauges take only a few seconds to set so you won't waste time between cuts.

Fine-Tuning the Miter Gauge to the Miter Slot

Precision miter gauges equipped with angle positioning stops make it just about impossible to make inaccurate angle settings. But setting the perfect angle won't lead to an accurate cut if there is "slop" between the miter gauge bar and the saw's miter slot. Even a small amount of play between the miter gauge and the miter slot can translate into crosscuts at inaccurate angles or a cut line that isn't straight, which in turn show up in your woodworking as gapped miter joints and cut surfaces that don't butt together properly.

Unlike most standard miter gauges, precision after-market miter gauges take the fit of the miter bar into account. Incra miter gauges, for example, are easily fine tuned to the width of the miter slot on almost any table saw with a quick adjustment to the unique expansion discs incorporated in their patented GuideLOCK system.

Supporting the Workpiece

Another problem with the standard miter gauge is that it doesn't provide much support for the workpiece as you run it through the saw. Especially when you are making angled cuts, it's important to make sure that the workpiece stays in position against the miter gauges fence. Crosscuts made at a sharp angle to the blade will actually have the tendency to pull the wood in the direction of the blade, causing inaccurate angle cuts.

A shop-built miter gauge fence will help to alleviate the problem but there are advantages to investing in the add-on miter gauge fence offered by as an option with many after-market miter gauges. Both Incra and Kreg offer a variety of miter gauge solutions, with a variety of optional fence systems.

And the options don't stop there. The Incra Miter Gauge 1000 offers the reliable workpiece support of a precision ground fence along with an integrated stop block system. The stop block is a handy feature that serves a couple of purposes: The stop block allows you to set up accurate cut lengths that you can repeat perfectly, without measuring - for the many projects that require multiple parts of the same length. It also makes it easy to keep the workpiece in exactly the right place during the cut, even in angled cuts where there's a tendency for the workpiece to slip.

Some miter gauges take integrated stop block design a step further too. There are some models that incorporate a flip-stop that can be tilted up out of the way of the front surface of the fence. This feature comes in handy in situations where you need to save a particularly important length setting while you use your miter gauge for other purposes.

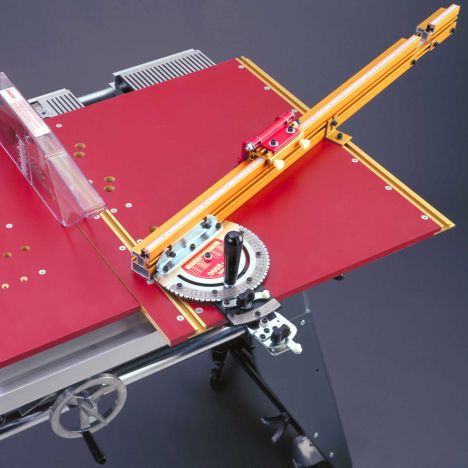

The Incra Miter Express Miter Sled

A precision miter sled adds another dimension to crosscutting accuracy and versatility. The Incra Miter Express is a two part crosscutting sled designed for use in conjunction with any standard miter gauge. The Incra sled is comprised of two panels: one fixed position "out-feed" panel (which provides a smooth level landing place for the cut-off) and a sliding panel that can be fine tuned to fit the miter slot on your table saw, and into which your miter gauge is quickly and easily "docked". During assembly, each half of the sled is trimmed to fit your saw, providing zero-clearance support on both sides of the workpiece.

The Incra Miter Express improves crosscutting of both very small parts and the ability to make wide crosscuts. The sled comes with an integrated hold-down clamp that keeps small parts in place against the miter gauges fence during the cut - and lets you keep your fingers well away from the blade (the T-slot into which the hold-down clamp is mounted can also be used to secure a variety of shop made jigs). The sliding bed of the Incra sled lets you dock your miter gauge in a variety of positions to accommodate various widths of cut, and in its maximum width setting, effectively doubles the crosscut capacity of most miter gauges to a full 24'.

The Incra Miter Express will automatically improve your crosscutting no matter what miter gauge you use along with it, but coupling it with a precision after-market miter gauge will give the complementary advantages of both - zero clearance cutting, safe cutting of very small parts, no miter bar wobble, and dead-on angle accuracy. The Incra Miter 5000 Sled is another option, it's design includes an integrated precision miter gauge and telescoping aluminum fence.

Which Table Saw Crosscutting System is Right for You?

The best miter gauge or miter sled for your shop will depend on the type of crosscutting work you do. If you use your table saw as a crosscutting tool primarily for standard 45 degree miters and the occasional odd angled part, a basic miter gauge will do. On the other hand, if your work takes you frequently into complex joinery operations involving precision other-than-standard angle cuts on very small parts, you might want to consider either the Incra Miter 5000 Sled, or the Incra Miter Express. If you find yourself often involved in projects that require crosscutting multiple parts of the same length, you should look for a miter gauge with an accurate, easy to set stop block. The Rockler Precision Miter Gauge, The Kreg Precision Miter Gauge System, and the Incra Miter Gauge 1000 all have exceptionally user-friendly stop block systems.

There is no shortage of reliable options, and each has the potential to significantly improve the crosscutting performance of your table saw. At Rockler, we offer a range of what we think are the best precision miter gauges and miter sleds, in a selection designed to offer a choice to suit the requirements and budgets of all woodworkers. Whichever system fits in with your woodworking style best, the important thing is that you realize the potential of your table saw for precision crosscutting work, and not let the fact that it came equipped with less than perfect crosscutting equipment stand in you way.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks