Not-So-Common Measuring Tools

When you're allocating funds for tools and equipment, it only makes sense to give a nod to the measuring department.

Measuring, measuring, and more measuring. Sometimes it seems like all a woodworker does. Get this blade set at the right height, double-check the length of that cut, make sure this dado is the right depth, spec the thickness of that pile of lumber... And it's important. Anyone who's ever tried to build anything approaching geometric precision out of wood knows that a couple of casual "close enough is good enough" measurements can haunt a project to the end. And with that in mind, here are a couple of specialized tools designed to make quick and accurate work out of common measuring challenges.

Measuring height is one of the most common and difficult to perform measuring tasks in woodworking. Everything form quickly ripping out a rabbet in a piece of stock to getting the coped joint on a frame and panel door to match requires an accurate judgment of the height of a blade or bit. But surprisingly, most woodworkers don't own a single tool that's well suited for this crucial purpose. The Digital Height Gauge is. In fact, it's designed specifically with the height measuring needs of woodworkers in mind.

The Digital Height Gauge offers a couple of key improvements over the usual method of balancing the blade of combination square on the tip of a saw blade or bit, or simply using a steel rule and your eyeball. For one thing, it takes all of the guesswork out of actually reading the measurement. The gauge offers up an easy to read display of the height in decimal form, with an accuracy of +/- .001”. The gauge can be zeroed out to the surface to the tool with a press of a button. Every time you use it, you'll be sure of getting an accurate, uncorrupted reading.

But every digital measuring tool does that. What takes the Digital height gauge beyond the now-common digital caliper as a height measuring instrument is its physical design. With its heavy steel foot, the gauge will rest flat on the surface of the tool of its own accord - which means that you'll be able to concentrate on other things, like judging when you have the tip of a table saw blade tooth positioned at top dead center, or simply reaching under your router table with both hands to raise the bit. The foot is heavy enough, in fact, that along with the option of presetting the height and bringing the bit or blade up to meet the gauge, you can rest the gauge's blade on the tip of the tool and raise both until gauge reads out the correct height.

The gauge's reach is another handy feature. One of the main drawbacks of other height measuring methods is they make it difficult to measure based on the guaranteed flat permanent surface of the tool - a much more reliable reference point than a table saw throat plate or router table insert. With the digital height gauge, you can take a measurement based on a surface that's a couple inches away from the blade or bit – in other words, base your measurement on the surface that's actually supporting the workpiece.

Getting things to end up in exactly the same (correct) spot on a number of parts is another of woodworking's most common measuring challenges. It doesn't take long for most woodworkers to learn that when it comes to repetitive measuring – cutting a number of parts to the same length, drilling holes that have to be in the same spot on multiple parts, stopped cuts on multiples, etc. – hauling out a tape measure and marking off each and every one isn't way to go. It’s almost always much more accurate and efficient to take the time to set up a jig or stop or some other type of auxiliary piece of equipment that essentially "does the measuring for you." That way, you only have to measure once – when you set up.

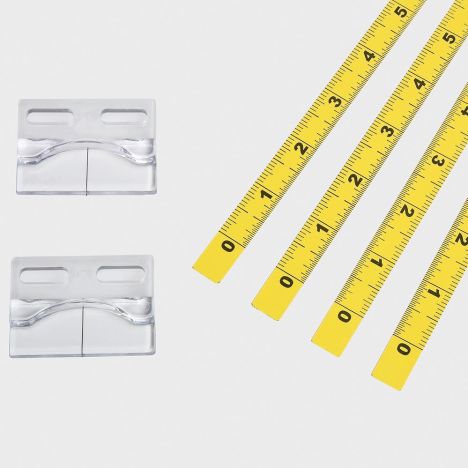

For length stops – one of the most common repetitive measuring aids – there's an even easier method: give the tool its own measuring device. We've all seen this in action. Every table saw has a measuring scale for fence settings. But where do you get the necessary equipment? Right here at Rockler – and you have a couple of options. Self-Adhesive Measuring Tape, sold in 6 foot lengths, is perfect for taking quick and easy measurements on a chop saw or radial arm fence. With both left-to-right and right-to-left number orientations available, you'll be able to line up and set a stop for both right and left hand cuts in a couple of seconds.

The 18" Measuring Kit for Jigs gives you the same convenient on-the-tool measuring set up, with the added accuracy afforded by an adjustable positioning cursor. The kit includes three each of left-to-right and right-to-left measuring tapes in 18” lengths and two cursors. It's ideal for the drill press, where repetitive positioning is practically the rule, and also great for stopped cuts on a router table, band saw or table saw. The measuring kit also makes a nice added touch to a shop built crosscut sled or miter gauge fence, and will also work very well as a length stop positioning system for a number of with a number aftermarket miter gauges. For t-slotted models, like the Rockler Miter Gauge Fence, just add a square scrap of wood a T-bolt and a knob and you're all set for accurate, quick and easy repetitive length cuts.

Measuring tools seem to be undervalued in woodworking - that's why we mention them so often. In truth, the investment in a few tools and gadgets that help make measuring reliable and easy can have a surprising impact on both the quality and speed of your work. Building up a measuring toolkit is also one of the most affordable ways to bring your work to the next level. (You can have all of the tools mentioned above for less than you spend on a couple of basic router bits.) If you're one of the many woodworkers who get by on a standard tape measure and a single (reasonably square) square, we urge you to take a look at what you’re missing in the world of marking and measuring. And while you’re there, take the time to read through a few customer reviews and see how much these sometimes overlooked tools mean to woodworkers who've seen the light.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks