Joinery for Drawers

What's the best joinery method for drawers? The answer: there are several reliable options. The best one for you will depend on the tools and skill at your disposal, and on the importance you place on durability, aesthetics and last but not least, getting done fast. In this article, we'll outline a few of the most common drawer making methods, and suggest a few tools that will make the process easier and more accurate.

Getting Started

A drawer is essentially just a box, but it's a box that has to be especially square (for the drawer slides to work correctly, among other things) and durable enough to stand up to the sometimes discourteous treatment that drawers tend to receive. In drawer making, the emphasis is on reliable, accurate joinery. Before your get started, you'll have two joinery decisions to make:

- How to join the bottom to the four sides

- How to join the sides to the back and front

Below, we'll take a look at both, and offer a few suggestions based on methods used by woodworkers for years.

Joining the Bottom to the Four Sides

Undersized Plywood Bits cut grooves and dadoes that fit the actual thickness of hardwood veneered plywood, which is usually less than the stated "nominal" thickness of the material.

While other methods of joining the bottom of a drawer to the sides exist, by far the most common is to slip the bottom into a groove at the bottom of the drawer sides so that when the four sides are joined together, they enclose the bottom. This method is easy to accomplish, and has the advantage leaving the drawer bottom free to expand and contract with changes in humidity, an especially crucial consideration for drawers with solid wood bottoms.

Cutting the groove for the drawer can be done with a table saw or a router and router table. On a table saw, set the cut height for a little more than half the thickness of the drawer side material, and cut a groove to fit the thickness of the drawer bottom material. A good spot for the groove is approximately 3/8" from the bottom edge of the drawer sides. The groove can be cut in several passes with a regular saw blade or, much more conveniently with a dado blade.

On a router table, run the stock face down using a straight bit to cut the groove. If you are planning to use hardwood veneered plywood for drawer bottoms (a good choice because of its dimensional stability) you'll get a better fit if you use an undersized plywood router bit. Undersized bits are made to match the actual thickness of plywood, which is usually slightly thinner than its stated, "nominal" thickness.

Joining the Drawer Front, Back and Sides

When it comes to attaching the sides the back, and especially attaching the sides to the front, opinions vary, and many joinery methods are championed. If you're new to drawer making, a good way to sample the available techniques and pick up a few tips is to start with a joinery book. Bill Hylton's Chests of Drawers covers drawer building basics as well as taking the reader step-by-step through a number of projects, all of which involve many drawer making opportunities.

Not surprisingly, Hylton and other experts single out a couple drawer joinery methods for their strength and aesthetic appeal. For joining the sides to the front, where the joinery is the most visible and under the most stress, the preference is for either half-blind dovetails or some other type of "locking" joint, such as that produced by a lock miter router bit. For joining the back to the sides, the standards are less stringint, and include joints that rely on simpler methods, like dado and rabbets.

The Classic Dovetail Joint

Left: Half blind dovetails leave the drawer's front surface intact, and are one of the most respected methods for joining drawer sides to a drawer front.

Right: Through dovetails signify "high end" craftsmanship They're a top choice for joining the sides of a drawer to the back.

The Rockler Dovetail Jig sets up quickly to cut either one.

Dovetail joints are without a doubt the king of drawer joinery. This venerated method has proven its mettle over the centuries and, for many people, represents the pinnacle of craftsmanship. Contrary to what you may have heard, dovetail joints are not all that difficult or time consuming to make, especially if you own a router and a dovetail jig.

There are many dovetail jigs on the market, ranging broadly in price and quality. We have our favorite: the Rockler Dovetail Jig. It's exceptionally easy to set up and use, and it makes perfect, square and tight-fitting dovetail joints very quickly. The jig package comes with everything you need to make classic half-blind dovetail drawer joints, but there are a few not-so-common features and options unique to the Rockler Jig that bear special mention:

The Rockler dovetail jig comes with both half blind and and through dovetail templates. Typically, a half blind dovetail joint is used for the front of a drawer. Through dovetails are most commonly associated with box-making and furniture-making projects where a decorative, visible joint is desired. But through dovetails are also a popular choice for joining the back of a drawer box to the sides, especially in fine furniture.

The Rockler jig, with it's tool free design and preset template positions for common material thicknesses, makes setting up for both half blind and through joints fast and intuative. If you decide to go the extra mile and have dovetails front and back, The Rockler jig will help you switch from one mode to the next quickly and repeatably.

Router bit chatter can pose a problem when cutting anything with tolerances as close as a dovetail joint. Typical 1/4" dovetail router bits - even those from the best manufacturers - can vibrate enough to create problems in the fit of the joint, and at the vey least, more noise and fatigue for the user. To alleviate this problem, the Rockler Dovetail jig now comes "standard" with Rockler's exclusive 8 millimeter router bit upgrade set. The 8mm dovetail bits' 25 percent thicker shanks greatly reduce chatter and vibration, while still fitting comfortably within the the guide bushing used with the jig. with the included adapter, the bits will fit in a standard 1/2" collet.

Cutting dovetails with a router and a dovetail jig is many times faster than making the same joint by hand - but there is a tradeoff. The evenly spaced, mechanical-looking pins and tales produced by the typical dovetail jig template can seem uninspired. The optional Distinctive Series Dovetail Templates available for the Rockler Dovetail Jig give woodworkers the opportunity to create a custom, handcrafted look, without the added expense and set up that typically accompanies a jig with variable-position guides.

The Drawer Lock Joint

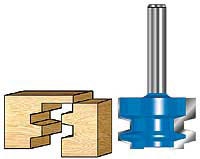

Another solution is the drawer lock joint. A drawer lock joint consists of two specially shaped interlocking rabbets that allow the drawer front and back to be securely glued to the drawer sides. The method is somewhat less durable than a dovetail joint, but strong enough for average drawer use. In it's favor, the drawer lock joint is extremely quick and easy to make.

To construct a drawer lock joint, you need a router, a router table, and a drawer lock bit (a single bit cuts both of the necessary profiles). If you already have the router and table, then getting set up for drawer lock joinery is simple and painless - A Rockler Drawer Lock Router Bit represents only a modest investment and comes with an unconditional guarantee. Adding a Rockler Drawer Lock Bit Set-Up Jig is worth considering. The durable plastic set up jig will virtually eliminate any trouble you might otherwise have getting the cuts to align.

There are many other possible methods for joining drawer drawer box members. Some woodworkers will go to the trouble of making a sliding dovetail joint for the sides and front. Others are perfectly happy with a dado joint and staples for both front and back. Of course, the easiest method of all is to let someone else build your drawers. With the Rockler Custom Drawer Program, you can solid hardwood dovetailed boxes delivered to your door, ready to stain and finish. But whatever method you choose, you'll find everything you need to make perfect drawers at Rockler.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks