How to Get Started in Woodturning

Woodturning is a fun skill category within the world of woodworking. Unlike many types of woodworking, instead of assembling multiple pieces of wood to make something, woodturning is similar to carving, meaning that it requires removing wood from a single piece to create the finished project. Woodturning appeals to many because you don't need a large space or a lot of tools to get started.

What tools and materials do you need to make your first woodturning project?

1. A lathe.

2. Woodturning tools.

3. Material to turn, such as wood or acrylic turning blanks.

4. Work holding devices.

5. Apparel.

Video: How to Get Started in Woodturning

What do you need to get started in woodturning?

#1 - A LATHE

No surprise here: You're going to need a lathe. But which lathe? Besides the array of brands available, lathes come in a range of sizes. How do you know whether you should get a mini lathe, midi lathe or full-size stationary lathe? Your choice obviously will be influenced by your budget and the space available in your shop, but you'll also want to think about the kinds of projects you'd like to make.

Do you want to try pen turning? We have many small project turning kits to help you get started. Do you want the flexibility to turn just about anything, regardless of size? Answering these questions is important because they relate to several key technical specifications that can help you narrow your search for a lathe.

Video: Rockler 10 - 18 Mini Lathe

Video: Rockler VS 12-24 Variable Speed Midi Lathe

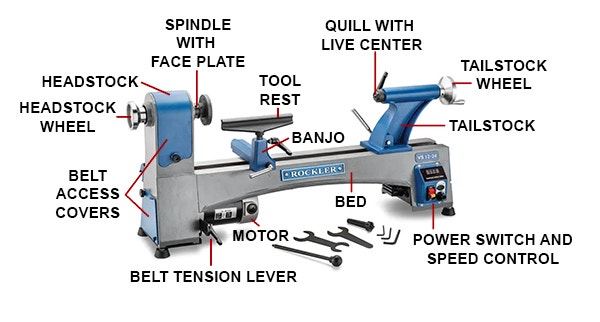

Video: Learn the Parts of a Lathe

Technical Specifications to Consider When Choosing a Lathe:

Distance between centers: This is the distance between the drive or spur center on the headstock and the rotating live center in the tailstock when the tailstock has been moved away from the headstock as far as it will safely go. It tells you the maximum length of stock that can be turned on that lathe. So a mini lathe with a distance between centers of 18" can accommodate stock 18" long and shorter. That's not going to work for you if you want to be able to turn table legs, which typically are 28" to 30" long. In that case, you'd either want to look at a larger lathe or see whether a bed extension is available for the mini lathe to increase the distance between centers. But for turning smaller projects like pens, a mini lathe is a perfect size.

Swing over the bed: This is twice the distance from the tip of the drive or spur center down to the lathe bed. It tells you the maximum diameter that can be turned on that lathe – for example, a mini lathe with a 10" swing can accommodate a blank with a 10" (or just less than 10") diameter at its widest point. If you want to turn large-scale plates or bowls, you'll need a bigger lathe, but for small bowls and candy dishes, the mini lathe will work just fine.

Speed: First, what's the lathe's range of speeds? If you plan to turn large-diameter pieces, you want a lathe that can be set to a slow speed for safety reasons. That's because, at a given rpm setting, the outside edge of a big blank is traveling much faster than the lathe spindle. If the blank is spinning too fast, there's increased risk of vibration and the chance that the blank might fly off. Second, is it a fixed-speed or variable-speed lathe? Fixed-speed lathes offer a set number of speeds that typically are achieved by adjusting the position of a drive belt on sets of graduated pulleys attached to the motor and the spindle. Variable-speed lathes allow for a wider range of adjustment within given speed ranges, and adjustments are easier to make, because they typically will have a dial that can change the lathe’s speed instantly and incrementally.

Horsepower: A 1/2hp motor is adequate for a mini lathe and smaller turning projects. Midsize lathes will range from 3/4hp to 1-1/2hp, and larger lathes will range from 1-1/2hp on up. They’ll have ample power for turning heavier bowl or leg blanks and large platters.

Once you've decided on a lathe, you'll want to make note of two other details: the headstock and tailstock spindles' Morse taper and the size and number of teeth per inch (TPI) of the headstock spindle. Knowing these tech specs is important when buying such accessories as pen mandrels and four-jaw chucks for your lathe. Lathes typically have a No. 1 or No. 2 Morse taper (noted as MT-1 and MT-2), with MT-2 being most common. Common headstock spindle sizes are 3/4" x 16TPI, 1" x 8TPI and 1-1/4" x 8TPI.

#2 - TURNING TOOLS

Woodturning is a subtractive process – you create by removing material to reveal and shape the final form. Like a carver or sculptor, you need the proper turning tools to achieve the design and details you want. In terms of tools, you have two broad categories of options: carbide-insert turning tools and traditional turning tools.

Carbide-Insert Turning Tools

Carbide-Insert Turning Tools are great for both beginning and advanced woodturners. Carbide tools eliminate the frustration that can come with having to frequently sharpen dull tools. Simply rotate the carbide cutter for a fresh, sharp edge, and replace it once all available edges have become dull. The solid carbide cutter stays sharp longer than steel, giving you a much longer useful life.

The shaft on Carbide-Insert Turning Tools features a flattened back for stability when using the tool rest. Hold the tool perpendicular to the stock, rest the flat-bottom of the shaft on the tool rest and carefully push the cutter straight into the stock.

Carbide-Insert Turning Tools are available with several cutting profiles and in different sizes, depending on the types of projects you'll be turning.

Round (1 above): Features a round cutter. Used for roughing stock and cutting smooth beads, coves and other curves.

Diamond (2 above): Features a diamond point. Used for cutting grooves, small beads and other decorative details.

Square (3 above): Features a flat-edged square cutter. Used for roughing stock and forming smooth tenons

Square-Radius (4 above): Feature a square cutter with a slight radius that reduces the chances of catching a corner.

Traditional Turning Tools

As the name suggests, traditional turning tools have a long and respected history. For centuries, craftspeople have used these tools to create beautiful and functional turnings. In a skilled hand, traditional tools deliver superior results. The modern versions are made from tool steel or high-speed steel (HSS); HSS is preferable because it can withstand higher temperatures when sharpening without decreasing its hardness.

The Rockler Traditional High-Speed Steel Ergonomic Turning Tool Set (photo above) includes a parting tool, scraper, skew chisel, roughing gouge and spindle gouge.

Here's a brief introduction to the most common tools in this category.

Parting Tools (photo 1): These V-shaped tools are designed to cut or "part" off a finished spindle turning from the rest of the blank. They are available with either rectangular or diamond-shaped shafts, as well as in especially thin versions. Parting tools also are commonly used to cut grooves for marking cutting depths on spindle turnings with varied profiles.

Scrapers (photo 2):Used on bowls and spindle work to create smooth flowing curves and to reduce end-grain tearout.

Skew Chisels (photo 3): With their angled cutting edge, these tools are used in spindle turning to make smooth shearing cuts and to form V-grooves and beads. They're available in a number of sizes and with flat, oval or rounded shanks. The angled cutting edge can be straight or curved. Many turners find that a fair amount of practice is needed to master the skew chisel.

Gouges: There are three main types of gouges: roughing gouges (also called spindle roughing gouges), spindle gouges (also called detail gouges) and bowl gouges. The tools' names hint at the important differences between them.

Roughing Gouges (4) and Spindle Gouges (5): Both of these types of gouges are primarily used to turn spindles, which involves stock that usually is longer than it is wide and mounted in the lathe with its grain direction parallel to the turning axis. Roughing gouges are used to take stock from square to round, and spindle gouges are used for creating coves, beads and other details. In spindle turning, the lathe's tool rest typically is positioned close to the stock, supporting the tools close to the cutting edge.

Bowl Gouges: By contrast, when turning bowls, the bowl turning blank is usually mounted in the lathe with the grain direction perpendicular to the turning axis. The tool rest sometimes must be positioned several inches from the stock. As a result, bowl gouges (photo below) are machined with higher walls and deeper flutes to stand up to the increased stress they face because of the increased overhang at the tool rest.

The important takeaways here are to use the tools for their intended purposes and, especially, NEVER to use a roughing gouge to work on a bowl blank. It is likely to catch, and because it's not made to stand up to the stress of bowl turning, it might break and go flying.

Traditional Tools Need Sharpening

Traditional turning tools can deliver superior results, but they require more practice and require routine sharpening. Sharpening these turning tools is not difficult, but it is important to learn proper sharpening techniques. This is best accomplished with a slow-speed grinder or other dedicated sharpening machine, so an investment in this kind of equipment will be necessary. And, because free-handing the precise bevels on the different kinds of tools could prove difficult, special sharpening jigs might also be needed.

#3 -WORKHOLDING DEVICES

Spindle Turning

When turning spindles, the most common accessories used to hold the workpiece are a one-piece drive center mounted in the headstock and a ball-bearing live center mounted in the tailstock quill. Virtually all new lathes include these two parts as well as a face plate as standard equipment.

Bowl Turning

If you want to turn bowls, then you'll need either a faceplate (left) or a four-jaw chuck (right). Most lathes include a basic faceplate. The faceplate mounts to a bowl blank with screws. Four-jaw chucks are sold separately. They have moveable jaws that can hold workpieces in a variety of ways. You can use them to hold blocks and bowl blanks as well as spindles.

#4 - WOOD AND OTHER SUPPLIES

In theory, you can turn any piece of wood or acrylic and many other materials that will fit on your lathe, so long as the turning blank is sound and doesn't have any loose knots or other structural defects that might cause it to come off the lathe or damage your tools. For beginners, using a pre-cut turning blank is a good place to start.

Once you get a little experience, you can branch out. Sometimes you can salvage good turning stock from your firewood pile. Just make sure it's sound, and cut it into a blank that is as symmetrical as possible.

There are a wide variety of additional lathe and woodturning accessories that will make your turning experience easier, more efficient and more enjoyable. For example, the Dust Right® Lathe Dust Collection System plus Lathe Chip Deflector (above left) helps protect you from flying debris, and it collects dust right at the source. Additional task lighting is another valuable addition to your lathe setup. The Rockler Magnetic LED Task Light (top right photo) is easily adjustable to shed bright lighting wherever you need it, and the light beam adjusts from flood to spot. It's also a good idea to install a Turning Tool Holder (bottom right) to keep your turning tools close at hand.

If you're just getting started with woodturning, these Rockler Small Project Turning Kits are a great way to learn and create a beautiful project. They are not difficult to use, the projects don’t take long to make and you can end up with a very professional looking result. Rockler sells many kits, including pens, ornaments, rings and handles for all sorts of useful tools, such as bottle openers , pizza cutters , ice cream scoops , cheese knives , garden tools, and bar tools.

Learn More About Small Project Turning Kits

Learn More: How to Make Rings

#5 - PERSONAL APPAREL AND SAFETY

To grasp the importance of proper safety equipment and practices, it might help to remember that woodturning essentially involves poking a really sharp metal tool at a hunk of wood that's spinning really fast. You want to do what you can to keep anything from flying off the lathe and to protect yourself in case something does. At minimum, you need:

- A Face Shield, not just goggles; they can't stop a chunk of walnut burl from whacking you in the nose.

- A Dust Collector and respiratory protection. The federal Occupational Safety and Health Administration says wood dust exposure has been linked to allergic skin reactions, respiratory issues and even cancer. And contact with shavings, especially from exotic lumber, can cause skin irritation. Do what you can to protect your nose and lungs from excessive exposure to wood dust by wearing an N95 dust respirator and by using a dust collector.

- A Turner's Apron to protect your clothing and keep shavings from going down your shirt.

Other Safety Considerations

- If you've got long hair, tie it back. Don't wear dangling jewelry. Roll up long sleeves. Remove anything that might catch in the lathe.

- Make sure that your stock is mounted securely in the lathe and balanced to avoid excessive wobbling. Also, make sure to run the lathe at the appropriate speed for the stock. If the lathe starts walking across the bench or floor, slow down.

- Keep the tool rest as close as possible to the stock to reduce the chance of tools getting caught between the tool rest and the workpiece.

- Make sure the lathe is set up at the right height for you. Ideally, the center of the spindle should be at elbow height.

- When sanding, hold the abrasive against the bottom of the workpiece (where the direction of the spin is away from you). Be sure to remove the tool rest for added safety.

You're Ready to Start Turning!

All you need to get started woodturning is a lathe, a few turning tools, wood turning blanks and basic safety gear. Chances are that once the chips start flying, you'll be hooked on turning. And once you see how easy and fun it is to make one-of-a-kind gifts and special pieces for your own home, you'll be glad you didn't wait any longer.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks