How to Make a Wood or Acrylic Ring

Learn how to turn a ring. Ring turning is a project that offers a huge range of creative options. You can choose to turn a ring from almost any hardwood species or acrylic ring blank. You also have the choice of several styles of metal or ceramic ring cores. Turning rings does require more precision and attention to detail than some other types of woodturning projects, but it is not difficult if you take your time and work carefully.

VIDEO: Introduction to Making Rings

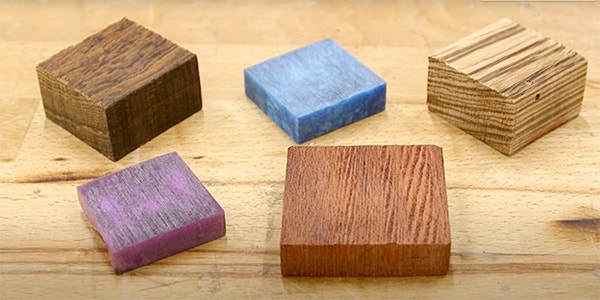

One of the fun and creative aspects of turning a ring is the wide selection of wood and acrylic Ring Blanks you can choose to make your ring one of a kind.

You can choose from a variety of one- and two-piece Ring Cores made from stainless steel, titanium, ceramic and wood.

One of the specialty tools that makes ring turning easier is a Ring Turning Mandrel. This tool features stepped cylinders that secure various ring sizes. Each step is 1/4'' wide, providing a stable flat and a secure grip for your ring. Choose from several size ranges to fit the rings you turn.

Accuracy is critical when turning a ring. An accurate and easy-to-use digital caliper, such as this iGaging 6'' Digital Fractional Caliper makes it fast and efficient to know the ring core will fit the ring perfectly. In addition to measuring inside diameters, this versatile instrument takes step, depth, external and internal measurements from 0-6" and displays them in inch, metric and fraction modes on a large, clear digital display.

These Micro-Mesh Cushioned Abrasives are washable and reusable abrasives are great for sanding small projects on the lathe! Unique cushioning design results in extended abrasive life, the best surface finish possible, and fewer steps. is used to securely hold the ring while shaping, sanding, and finishing the ring.

Project: Make a Ring with Crayons or Snakeskin Micarta

Project Plans: Make a Ring Box or Jewelry Box

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks