How to Deal with Twisted Maple

I have a bundle of hard maple 5/4 that I purchased at an auction. The vast majority is bird's eye. The problem is most is twisted. It is dry but appears to have not been sticked. I rolled the dice in buying, I know. The projects I build are, as a rule, seldom needing length over 18". My question is how to plane or joint flat and turn this potential heat source into usable material. - Dave Schlaufman

Chris Marshall: The upside to your purchase is that you have some extra stock thickness to work with. If you usually use 3/4 in. stock, you've probably got 3/8 to 1/2 in. of extra wood thickness with your 5/4 maple. Surface only what you need to use for the project you're working on (I follow that plan even with the best material), and cut your workpieces to rough length before surfacing. Then follow the usual surfacing regime: flatten one face, run the material through your planer to flatten the other face and bring it parallel to the first, then continue to reduce the thickness as needed. Even if you've got some pretty distorted stock, you'll probably end up OK, provided the pieces you need aren't extremely long. But, really badly twisted wood may have no other fate than the wood stove. One other thing: if you just bought that maple recently, or if it came from another part of the country than you live in, give it time to acclimate to your shop climate. Several weeks or longer never hurts. If you're not sure of how it was seasoned — and it sounds like you aren't — I'd find a moisture meter and check it before using the wood. Moisture content should be below about 10 percent before it's suitable for furniture-building.

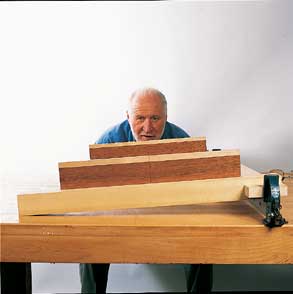

Rob Johnstone: Once a piece of lumber has dried out and distorted, you can flatten it and it will likely stay flat and true. The problem is that material on all faces of the stock will need to be removed to get it into a usable form, and that can mean that your stock might end up pretty thin. Cutting your stock to the shortest usable length that you can safely run across a jointer before you start surfacing the stock will mean that you need to remove less material to get it flat (18-inches is about as short a length as I would choose to face-joint). Of course, if you are using a hand plane to flatten your stock you can go shorter. After you have cut it to length, start by face jointing the stock on a jointer until one surface is flat and out of twist. (Winding sticks will tell you if there is a twist or not.) When you get a flat face, use the jointer to make a perfect 90-degree edge. Now you can step to the planer and surface the face opposite the one you made on the jointer. There you have it.

Tim Inman: This is basic Woodworking 101. Face, edge, end. End, edge face. That is the "correct" sequence for working a board flat and true. Begin by getting one face flat. Traditionally, this is done with a hand plane and a straight edge. If you're not into hand tools, then a jointer is your next best friend. Be sure the jointer is sharp, and the tables are set correctly for the cutterheads. You'll need to learn about "winding sticks" in order to get the board flat and not twisted if you must have long boards. A good book like "Feirer's Cabinetmaking and Millwork" will show you how it is done. Heavy use of a surface planer will usually just copy the twist onto your subsequently thinner boards. In other words, the pressure of the roller system in a planer just presses the wood flat while it is under the cutters, then the board springs back into its twist once it is free again. All this is to say just how important it is to sticker and dry wood correctly.

So, have you bought firewood? No, I don't think so. Cut those boards shorter to make useable pieces. If you can make judicious cuts to minimize the twisting and distortion, you should be OK. You will have shorter pieces, of course, but you should be able to flatten them without much twisting. Maple is very hard. If you use a really sharp surface planer, and reasonably shorter pieces (not too short!) and gentle, light cuts, you can probably plane those boards flat and pretty - without too much waste. I'll get lots of critical feedback about this answer, but I've done it many times. It isn't textbook, but it can work. More skill, less force, as my Dad always taught me! Good luck.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks