Hand Saw Overview: Veneer Saws

Veneering is an age old technique for adding the beauty of exotic woods to a project without the cost of using full pieces of rare hardwoods. Even adding small inlays and medallions can really take your project to another level. Veneer saws are the right tool for getting your best results.

Large sheets of veneer can be cut on the table saw and trimmed off with a router, but very small pieces can be cut and used for exquisite details on a high end project. Only the proper hand saws will allow you that control.

Thin veneers can be cut with a sharp knife, but knives tend to follow the grain and leave a rough edge. Sawing the veneers gives a square edge that allows for tighter joints in inlays or patterns.

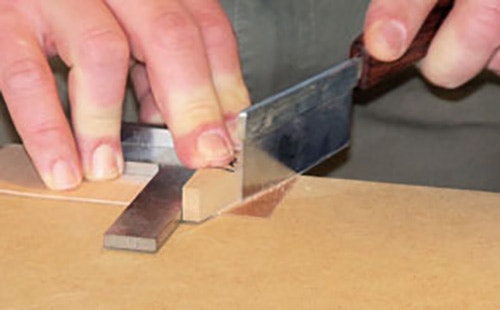

Note how the blades of both of these saws are curved. This curve allows you to start a cut inside the veneer sheet without needing to start at the edge. It also provides very precise control during the cut. The blades are thin with virtually no “set” to minimize the kerf line. The handles are offset and well above the cut line to allow tight cuts along a straight edge.

Contrasting veneers can be laid up to form colorful medallions that add a lot of interest to large flat surfaces. I cut angled blocks of MDF to guide my veneer saws as I piece together the rays of an oval medallion. Keeping the saw square to the guide creates flat clean edges that join together well.

It will astound you how versatile these simple saws and a few scraps of thin wood can be when it comes to decorating your project.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks