Getting Dadoes and Plywood Thickness to Match

Have you ever used a 3/4" router bit to cut a dado for a plywood shelf, only to discover that "three-quarter inch" plywood isn't all that it claims to be? It can be a shock the first time; you're left a plywood-to-dado fit that has more than just a little "slop". In fact, the typical sheet of 3/4" plywood actually measures close to a hefty 1/32" less than its nominal thickness would lead you to believe.

So, how do you get your dados to match the actual thickness of common sheet materials? Using "undersized" plywood router bits is one of the simplest routes. Undersized router bits come in odd sizes that reflect the usual actual thickness of a standard sheet of hardwood veneered plywood, the most useful being 23/32" and 15/32" for plywood commonly sold as 3/4" and 1/2" respectively.

Undersized router bits aren’t the perfect solution. They'll give you a perfect fit sometime, and they'll almost always get you close, but no sheet of plywood is actually guaranteed to be any exact thickness. As we all know, wood expands and contracts with fluctuations in humidity, and a piece of veneer core plywood is no exception. Also, plywood is manufactured to standards that allow for variations in thickness of up to 3/64" for plywood sold in nominal thicknesses of 1/4" and more. If you want a perfect plywood-to-dado fit, you’ll have to take another approach.

On a router table, the "two pass" method with a few test cuts and some skillful fence positioning will get you a dead-on fit, but the process can be maddeningly slow. You can speed things up (with dadoes and in general) by treating yourself to a fence with an accurate micro adjustment system, like the Incra Lead Screw Router Table Fence. And while it’s not the kind of thing most of us would pick up on a whim, a precision fence system is worth some thought, especially if you’re planning to take up precision router table work on a regular basis.

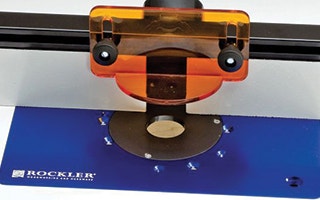

The same accuracy can be achieved on a table saw using a dado blade. But with a typical stacked dado set, you’ll still be looking at two passes – one to hog out the majority of the material, and a second to fine tune the width of the cut. The tricky part, again, is getting set up for an accurate second cut. Most table saw fences won’t make the necessary fine adjustment a simple matter: Typically, you'll have to whack it around with the heel of your hand and make test cuts until finally it lands in the right spot. But there’s a simple solution: the Magnet Micro Adjuster. It's an affordable add-on, and with it you’ll be able to dial in the perfect fence position in a couple of seconds.

Finally, if you really want to laugh in the face of vagaries in plywood thickness, get yourself a dado blade with true micro adjustment capabilities, like Freud's Dial-A-Width. That'll make matters about as easy as they get. Here’s the refreshingly simple procedure: Stack up the appropriate number of chippers, set the micro adjustment dial to the desired width, make a test cut if you feel it's necessary, and start cutting.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks