Finishing Outdoor Furniture

Many people believe exterior varnish is more waterproof. It's not. Nor will it entirely prevent sun fading or darkening.

As it turns out, the most important difference is flexibility.

Moving With the Weather

Wood moves with variations in humidity. Since outdoor humidity typically varies far more than indoors, outdoor wood moves more. Therefore, exterior finishes must be flexible enough to tolerate this extra wood movement without cracking.

Unfortunately, more flexible finishes are often softer as well. Thus, the manufacturer's goal is to create the ideal combination of flexibility and durability.

Before You Finish

As with all projects, it's easier to finish the individual parts before assembling. This is not always possible, but when you can, consider doing it. You can brush or spray any coating, but if you choose oil-based, my favorite method is to flood the finish on and wipe off the excess evenly. It's quick, simple, dust-free and nearly foolproof. Add as many coats as you like, but only one per day.

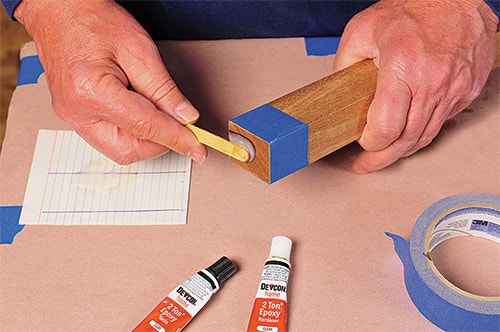

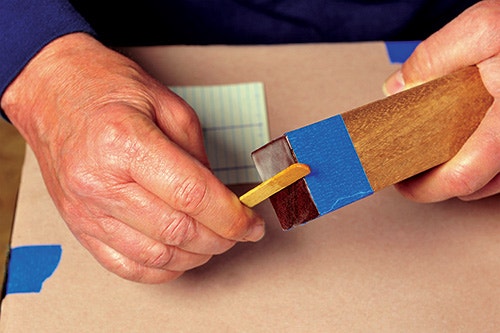

When the feet of chairs and tables sit on wet surfaces, any exposed end grain can soak up water, often causing cracking and premature rotting at the bottom. To stave that off, I like to seal the end grain on feet and legs before finishing. Here's how I do it.

Mask off the sides, leaving only the end grain showing. Mix a good exterior epoxy, preferably one that is fairly thin, and slather it liberally onto the end grain. Let it soak in a bit before scraping off any excess. Once the epoxy cures, you can lightly sand any roughness.

Choosing a Finish

Choosing a finish raises a few questions. Should I use water-based or oil-based coatings? Would I prefer long life or ease of maintenance? What look do I prefer?

Wood movement can cause brittle lacquer to crack or craze. Water-based and oil-based exterior varnishes may look a bit different, but either can be quite durable. As a rule, water-based coatings dry faster and smell less. Slightly more amber oils tend to bring out more color and depth to some woods, and usually give you more working time. You'll notice I’ve avoided discussing shellac and lacquer, as both are too brittle for exterior coatings.

Durability? Simply put, a high quality oil-based coating will outperform a poor quality water-based one, and vice versa. Should you want to add color, both come in tinted and opaque options, and both can be tinted with pigment or fade-resistant dye.

Deck Coatings vs. Oils vs. Exterior Varnish

Yes, you can finish furniture with deck coating, which comes in clear, semitransparent colors and opaque colors. The last two are usually called deck stains, and the opaque version looks like very low-luster paint.

They are usually fairly inexpensive and easy to apply, but wear more quickly than varnishes. Hence, they require more regular maintenance. You won't often need to strip the finish, but to keep everything looking good, you'll want to clean them and reapply another coat every year or two, depending on the amount of wear and exposure the furniture gets.

Another option is pure tung or linseed oil. Both are cheap, easy to apply and sufficiently flexible. Neither, though, will last very long, so figure that you'll need yearly recoating to keep up with the ravages of time and weather.

Varnish will last a good bit longer, but when it does start to go, it may begin to peel. At that point, your best bet is to strip it off and reapply, and that's a lot more work. If you have one, a pressure washer can be a real boon for this. It's quicker and less messy than chemical strippers, and easier than sanding. For that matter, a pressure washer is also a great cleaning tool for yearly maintenance. Just set it on a lower power or use a wider, larger fan tip.

The Naked Option

By far the easiest option is to leave the wood unfinished, as seen in this article's lead photo, and let nature age it gracefully. A naturally rot-resistant wood will often do just fine unfinished, and many develop a lovely silvery hue over time.

What about pressure-treated wood? It, too, can often be left alone, and will discolor more slowly than most natural woods. If you want to stain or finish it, the rules are the same as with any exterior wood: make sure it is dry enough and the surface is clean. Some pressure-treated wood may arrive very wet, and finishes adhere better when the moisture content is around 14% or lower. Checking it with a moisture meter can save you headaches later.

Additives

Some exterior coatings contain UV blockers and absorbers to help offset sun damage, and many contain mildewcide and fungicide, to prevent mold and mildew growth. If you have a particular mold problem in your area, you can add these "preservatives" to almost any finish. You'll find them in small bottles or packets online or in the deck coating section of your store.

A Traditional Alternative

So, what's my favorite? I lean toward oils, and at the top of the list is true spar varnish. Although the word "spar" may appear on any coating, traditional spar varnish is a mixture of tung oil and phenolic resin. Both ingredients have natural resistance to UV damage, and the combination is sufficiently flexible, so it holds up well. What's unique about it, though, is that it tends to wear from the top down.

When most alkyd and polyurethane varnishes start to fail, they often do so at the wood-to-finish interface. In other words, they peel. True spar varnish generally starts to get chalky on the surface long before it will fail at the wood line. Thus, you can simply sand the chalky surface and reapply another coat. Attended to diligently, you can keep a spar varnish going indefinitely without ever stripping it.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks