Cutting Exotic Hardwoods?

I'm working with an exotic hardwood that's so tough my band saw will not cut it. The blade just burns through the cut. My table saw and circular saw don't do much better, and my jigsaw only did so-so. My chainsaw will cut through it, but that's about it. What kind of band saw blade do I need to cut this wood? I broke the first blade and, by the way, these are brand-new blades. – William Bunting

Tim Inman: I'm not sure what wood you are working with, so I will just address typical hardwoods that are unusually hard. As a turner, a special elite group of liveried tradesmen of yore included a sub-class known as "hardwood and ivory" turners. Colloquially, they called themselves "bone grubbers." These were the craftspeople who made things from bone, ivory, amber, African blackwood, ebony and the like. Their woods were not just scientifically classified as hardwoods but also equally difficult — hard — to cut. African blackwood (see photo, below) is the wood typically used to turn clarinets and bagpipe pieces. It is hard as glass and heavy. I think many black piano keys were actually blackwood instead of the commonly associated "ebony." Regardless, they all share some similar cutting characteristics.

I like to turn ironwood (sometimes known as lignum vitae), Osage orange or "beau d'arc" or hedge, and boxwood. They not only are hard but also often contain mineral deposits inside the wood cells that are abrasive to the cutting tools. In all cases, I find that a slower cutting speed is very helpful. If I can slow down the rpm on the lathe or the feet-per-second rate (fps) on my saw blades, I get better cutting and longer blade life. Sawyers often use a liquid cutting fluid when they saw green logs into lumber. I have never tried this with my cabinetmaker's saws, nor will I. The effect of a liquid in the saw kerf might cause the wood to bind the blade and cause accidents.

Slower speeds have almost always been my friend. So, if you can slow down the saw blade with belting adjustments, that would be one way. Another way to slow down the cutting speed on a circular saw is to use a smaller diameter blade. Circular saw cutting speeds are measured in fps, not rpm. So the distance around an 8-in. blade is much less than the distance around a 12-inch blade, given that they are turning at the same rpm frequency.

Counterintuitively, don't go gently when you make the cuts. Don't let the saw tooth just rub and polish against the wood. Be judiciously forceful and make the cut in a determined way. Let the saw tooth bite into the lumber. Don't be a bully and force the cut, but don't just let the abrasive wood wear away at the blade either. Carbide cutting edges would be my only option. Anything else is just a frustration in the making. Be sure the wood is not closing at the cut and pinching the blades, too. You might need to add something to the cut to keep the kerf open while you're in process.

The reason the turners had a special liveried division for hardwood and ivory work is that it is very difficult to do, and it requires an advanced degree of skill and specialization. Take heed, but do try! Good luck.

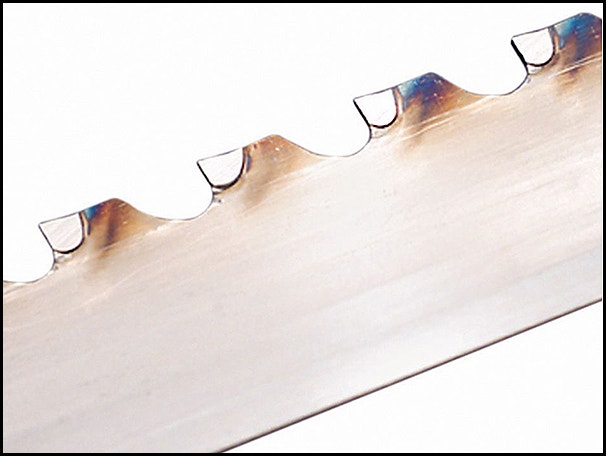

Chris Marshall: Following Tim's advice about carbide, here’s a bit of band saw blade information that might help your cutting situation now, William, or maybe at a future time. Laguna Tools sells C4 carbide-tipped band saw blades that are designed primarily for resawing (see top photo). A quick check of their site reveals that the company’s Resaw King blades are manufactured in several widths down to 1/2-in., at 3 to 4 variable teeth per inch. While that wouldn’t be an ideal choice for cutting curves, it should work fine for basic ripping and crosscutting your hardest stock, plus it will take care of your general resawing needs. Laguna offers many blade lengths, so surely there’s a size to match your machine. But brace yourself for some sticker shock — carbide-tipped band saw blades don’t come cheap.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks