Common Table Saw Cuts

Cutting along the length of a solid-wood board with the grain direction is referred to as a rip cut. The cut is nearly always guided by a rip fence attached to the table saw. The cut will be most accurate if the edge that runs along the fence is straight. When you rip a board you are cutting it to a specific width.

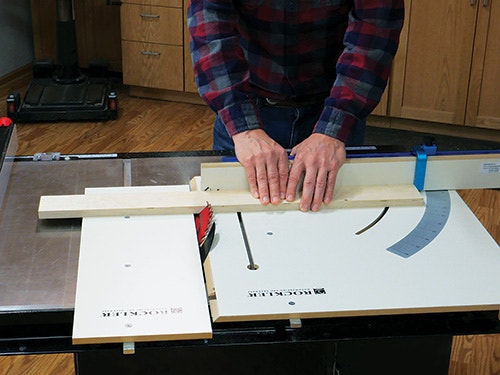

Crosscutting is when the saw is cutting across the grain of the lumber. The length of a board is determined in a crosscut. Crosscutting on a table saw is safely done using a fence that is set at 90 degrees to the saw blade. A crosscut sled or miter gauge are the most common means of creating accurate crosscuts.

The terms are a bit less accurate when cutting sheet stock. Plywood, MDF, particleboard and the like do not have true grain direction that determines the type of cut being made. Even so, the table saw is still adept at cutting sheet stock into precise panels. Once again the pieces being cut are guided by a fence of some sort.

Advanced Common Cuts

While that old-fashioned saw of my youth faithfully ripped lumber day after day for years on end, that was really about all it was good for. Modern table saws, on the other hand, are tremendously versatile and can cut and shape wood in a variety of ways. Some of the more advanced but still common cuts are miters, tapers,grooves and dadoes as well as forming tenons, bridal joints, box joints, half-lap joints and more.

Miter and taper cuts require an accurate and safe miter fence or jig to hold workpieces at an angle to the blade. Grooves or dadoes are typically made with a special cutter known as a dado blade, and raising tenons can either be done with a miter gauge or a special tenoning jig. The same is true of box joints; a shop-made or manufactured jig is required to cut a series of repetitive slots and fingers that fit together within close tolerances.

More Advanced Cuts

Occasionally you can employ your table saw to make even more interesting cuts such as cove cuts. Again making use of a jig, they're easy to do. And while we may properly consider raised panels the bailiwick of router tables and shapers, in a pinch you can make perfectly functional raised panels using your table saw and a standard.

Another ability of the table saw is that it can be used to create decorative shapes. Bevels or grooves in repeating patterns are easy to form with a table saw. And spline joints, which can enhance a miter's strength or simply be decorative, are a piece of cake to make.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks