Choosing a Crosscut Sled

Many woodworkers find that a crosscut sled has a couple of appreciable advantages over a miter gauge.

What's the best way to improve upon the not-too-accurate miter gauge that came with your table saw? Fortunately, any of a number of options will help bring out your table saw's crosscutting potential - and you don't have to settle on just one. A very popular choice is to head out and buy an aftermarket miter gauge. Another option is to set yourself up with a crosscut sled.

With a sled, the workpiece doesn't come in contact with the surface of the saw at all, but instead rests on the sled's platform and is supported from the bottom as well as from behind. That makes keeping the stock from slipping out of position during the cut much easier. It also gives you a degree of control over the amount of friction you have to overcome during the cut: you can take measures to make the bottom of the sled slicker such as waxing it, or applying a couple strips of lubricated tape - which is something that can't, or at least probably wouldn't, do with the stock itself.

Along with that, most sleds are designed so they pass the blade at zero distance from the cutting surface of the teeth, giving you the "zero clearance" support that helps reduce tearout at the bottom of the cut, and also makes it easier to position the stock (you just line up where you want the cut to begin with the edge of the sled and voila - the stock's in position).

Crosscut sleds come if a variety of shapes, sizes and designs; you can even build one yourself. Just about any table saw book will have a plan for, or advice on building a basic crosscutting sled. But there's a drawback to build-it-yourself approach: shop-built sleds tend to be very limited in what they can do. It's a fairly simple undertaking to build a sled that will cut a single angle accurately and reliably - such as 90 degrees - but building a sled that sets up quickly and accurately to cut any angle you need is much more difficult.

Most aftermarket sleds, by contrast, are designed to give you a full range of angled cut positions. Along with that, better store-bought sleds are engineered to make setting up for angled cuts quick and easy, and produce accurate, reliable results. They slide easily, usually have some provision for adjusting the fit of the guide bar in the miter track, and often have sophisticated, super-straight fence systems. All of these features add up to make buying a crosscutting sled instead of building one an attractive option, even if it costs a little more.

So, if you decide go that route, which one should you buy? As is the case with aftermarket miter gauges, there are a number of makes and models to choose from, and a fairly broad range of price tags to go along. Out of the bunch, we have our favorites in all price ranges. You won't find a more trusted name than Incra for jigs, fences and sleds of all types. The Incra Miter Express would make a very worthy choice, especially if you already have a quality miter gauge to install in it's unique "docking" system. If you're feeling a little more cashy, the Incra Miter 5000 Sled is loaded with advanced features and will make even the most discerning woodworker beam with pride.

But you don't have to spend a fortune on a crosscutting sled to have all of the important bases covered. The Rockler Table Saw Crosscut Sled is designed to combine the best and most important crosscutting sled features in an especially user-friendly and affordable package. Here's a quick rundown on what we think makes this recently introduced option an excellent choice for woodworkers with an equally keen eye for accuracy and a good deal:

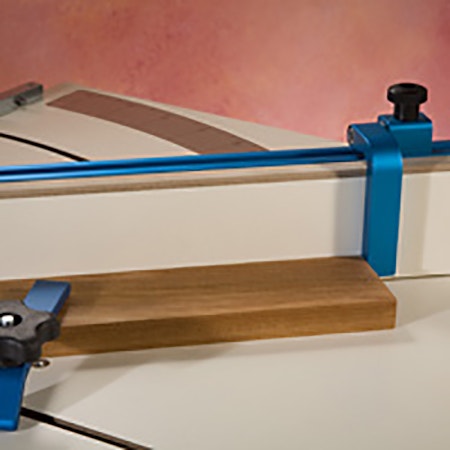

The Rockler sled's 23-3/4" square melamine coated platform provides ample workpiece support. It comes with a little added width on the blade side, which trims down the first time you use sled to provide the all-important zero blade clearance fit with just about any saw. To make sure the platform travels easily, the Rockler sled comes with 4 pieces of self-adhesive low friction tape, and to make certain that it travels accurately, the guide bar is equipped with spring loaded ball bearings that adjust easily to take out any slop in the miter track fit.

The Rockler sled's extruded aluminum fence is equipped with a removable, adjustable MDF fence facing that can be set to provide a sacrificial zero clearance support for the back of the workpiece and replaced when necessary. For repeat cuts, the package includes a 90 degree adjustable stop that pivots up out of the way (so that you can save an important length setting while you use the sled for a longer cut). To help hold the stock securely in position while you keep your fingers out of harm's way, you also get an integrated hold-down clamp that can be positioned anywhere across the majority of the platform's length.

But what really sets the Rockler sled apart is how easy it makes setting up for angled cuts. The angle scale is laid out in an arc on the left side of the platform. Instead of squinting at miniscule hash marks on pivot end of the fence, you can zero in on easy to see, generously spaced lines with the fence's hairline cursor. That, along with the easy to grip hold-down knobs that lock the fence in place make the Rockler Sled just about as easy to set up as is mechanically possible.

A well designed sled can greatly increase the crosscutting accuracy and efficiency of just about any table saw. Especially if you frequently engage in close tolerance work with small parts, you'll notice the difference right away. And with the Rockler Table Saw Crosscut Sled, you now have the option to open up a new world of crosscutting ease and precision at an especially attractive price.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks