Band Saw Blades: Five Fast Facts

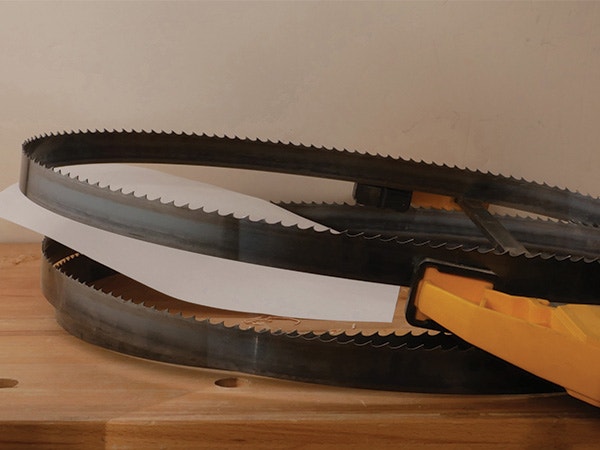

Probably no one goes into their shop and gazes on their band saw blades with awe and affection. And why should you? They're reasonably inexpensive pieces of steel that don't draw attention until they break. But let's stop and consider for a moment how amazing they are and the useful services they provide. Time to give them a little respect!

1. It's all about the blades. A British band saw patent was filed in 1809. But the technology to create durable band saw blades (the welds broke quickly) kept band saws from being a practical tool for the next many years. A patent by Anne Crepin, a Frenchwoman, solved the welding problem in 1846, and the way was made clear for band saws. The American band saw patent was filed in 1836 by Benjamin Barker of Ellsworth, Maine. (Apparently it had to wait for a suitable blade as well!)

2. Size matters. Woodworking band saw blades are generally made of carbon steel. The width of the blade is the key determinant as to how small a curve or diameter you can cut. A 3/4"-wide blade's minimum cut diameter (about 5-1/2") is much larger than a 1/4" blade (approximately 5/8"). On the other hand, wide blades usually cut straighter lines than narrow blades, if they are sharp.

3. Those are some fine teeth you have. Tooth count varies on band saw blades. In general, narrow blades have more teeth per inch and cut smoothly but require a slower feed rate. Wide blades have fewer and larger teeth per inch. They cut more roughly but are stronger, to handle much thicker material. The larger gullets between their teeth allow more swarf to be removed with greater efficiency while producing less friction.

4. Two to tango. There are two main types of tooth configurations: hook tooth and skip tooth. The hook tooth has about a 10-degree rake angle, allowing more aggressive and faster cutting. Its trade-off: a rougher cut. Skip tooth blades will not cut as quickly but leave a much smoother surface on the wood, requiring less sanding on exposed edges.

5. Jack of many materials. While we primarily cut wood, band saw blades are available that cut many different materials. Plastics and non ferrous metals (brass, copper and aluminum) can also be cut with the proper blades on a standard band saw. Carbide tooth blades are a relatively new technology that provide high quality cuts and remain sharp for a long time.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks