All About Band Saw Blades

Today, band saw blades are marvels of engineering and are the key to getting the most from your machine.

The three most common blade types in a woodworking shop are bi-metal, carbon steel and carbide-tipped. Carbon steel blades are highly functional and might be considered the most "basic" blades. Bi-metal are made by laminating a strip of high-speed steel to a carbon steel blade before the teeth are ground. These blades work fine on wood and can cut non-ferrous metal as well. Carbide-tipped band saw blades are extremely useful for tough jobs like resawing, because their teeth stay sharper longer than the other two blade types.

As you might expect, the more complicated the process to make a band saw blade, the more expensive they are. Carbon steel is the most affordable, bi-metal is next and carbide-toothed blades are most costly — each tooth must be ground individually with diamond wheels.

Band saw blades are welded into a circular loop. The spot where they are welded together is a common point of failure. Before putting a blade on the saw, it is a sound idea to inspect the weld. If there are obvious cracks, don’t use that blade. (If it is brand new, send it back for a replacement.)

The width of a band saw blade is the limiting factor in terms of how tight a radius you can cut. In the chart below, you can see the approximate limits for common band saw blades. The rule of thumb for cutting curves is, the skinnier the blade, the better. If you are resawing, use the widest blade your band saw can handle.

Counting Teeth

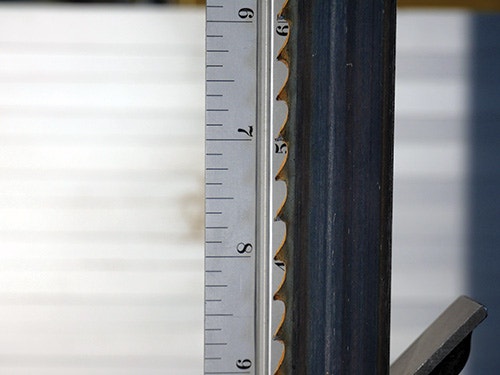

Another variable of band saw blades is the number of teeth per inch (TPI). Higher tooth counts produce smoother cuts with finer saw marks. Fewer teeth, 2 or 3 TPI for example, create coarse cuts with clearly visible saw marks. So why would you ever want to have fewer teeth per inch? The answer has to do with sawdust. If you are making a deep cut with a band saw, say resawing a wide board or cutting a bowl blank out of a log section, there will be a lot of sawdust created. If the gullets are not deep enough to catch and remove the sawdust (in this situation we call it swarf), the swarf will cause the blade to cut poorly or maybe not at all. Saw blades with high TPI have very shallow gullets — those roundish "pockets" between the teeth. With lower TPI, the gullets can be deep and large to remove a lot of swarf.

And finally, the set of the teeth affect how band saw blades perform. The term "set" when applied to saw blades is the amount of angle that the tooth deviates from the body of the blade. Blades with few TPI generally have wider (more aggressive) set, while high TPI blades have narrower set. Wide set helps clear swarf more effectively, while narrower set leaves a smoother cut. There are also variations in tooth shapes or series of set/shape — skip tooth, hook tooth or raker configurations.

These variables interact with one another and can make blade choices complicated. So here's another rule of thumb: for cutting thicker wood, green wood and resawing, use a wide blade, 2 to 3 TPI with an aggressive set. If you're cutting tight curves, use a narrow blade with 10 to 12 TPI. For almost all other cutting, gradual curves, ripping and crosscutting, use a 1/2"- to 3/4"-wide blade with 6 to 10 TPI in any configuration and set.

|

Blade Width |

Minimum Radius |

|

1/8" blade |

1/4" radius |

|

3/16" blade |

1/2" radius |

|

1/4" blade |

3/4" radius |

|

1/2" blade |

1-1/4" radius |

|

3/4" blade |

2-1/2" radius |

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks