Toggle Nav

Types of Wood Hand Planes

November 06, 2024

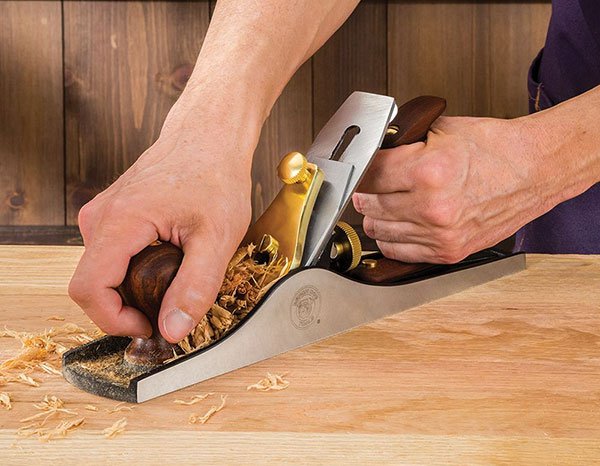

The hand plane is a truly iconic woodworking tool. Hand planes feature a blade that is mounted in a wood or metal body. The blade is extended through the bottom of the body and the hand plane is pushed or pulled across a wood surface to remove thin layers of wood, leaving a smoother or reshaped surface. Hand planes are designated by number, the higher the number, the longer the sole of the plane. You can use a hand plane to do quality woodworking as well today as you could a hundred years ago.

Video - Introduction to Hand Planes

Types of Woodworking Hand Planes

Smoothing Planes

We will start with the bench planes, a type of hand plane that is typically use at a workbench and handled with two hands. In traditional woodworking terms, the No.1 through No.4-1/2 bench plane models are often referred to as Smoothing Planes . These general-purpose hand planes are most often used to smooth a wood surface before finishing. Hand planes typically get larger and heavier as the model number increase.

The smallest of the smoothing planes is the No.1 Smoothing Plane (left). It is a smoothing plane in the small size of a block plane. It is typically held with one hand, with the tote tucked into the web of your thumb and your fingers lightly cupping the cheeks of the plane. The No.4 Smoothing Plane right) is nearly twice the size of the No. 1, but they can both accomplish similar tasks. The No. 4 is arguably the most commonly used bench plane. It features a 2”-wide blade and a 10”-long sole. The slightly larger No.4-1/2 Smoothing Plane features a 2-3/8”-wide blade and 10-1/4”-long sole. The wider blade and additional weight allows the user to to plane the wood surface with fewer passes.

Jack Planes

The No.5 through No.6 bench planes are often referred to as Jack Planes. These planes are excellent general use planes and can perform most planing chores. It is commonly used for shaving doors that stick, leveling high spots on glued-up panels and a host of other tasks. One of the best uses for these mid-sized hand planes is jointing edges for gluing. Set a light cut, and let the long base of the plane ride over the edge, taking down the high spots.

The No.5 Jack Plane is longer and heavier than the No. 4 smoothing plane. This planet is often used to remove a lot of materials and work a board down to its final thickness.

One of the most versatile planes available, and one that continues to gain popularity, is the No. 62 Low Angle Jack Plane. Thanks to its adjustable mouth and 25° blade that is set bevel-up at a low bedding angle of 12°, it can take rough surfacing cuts, fine smoothing cuts, and handle challenging grain equally well.

Jointer Planes

The Jointer Hand Plane is the longest and heaviest plane in the bench plane lineup.

The No.7 Jointer Plane weighs nearly 8-1/2 lbs and features an extra-long 21-7/8"-long sole that quickly levels dips and high spots—ideal for edge jointing and final flattening of surfaces before smoothing.

Block Planes

In contrast to the bench planes, a Block Plane is typically used with one hand and excels at smoothing mill marks, chamfering sharp edges, truing up miters, and trimming doors to fit.

The size and versatility of the No.60-1/2 Jack Plane makes it a popular choice for most woodworkers. The mouth opening is easy to adjust to achieve the finest shavings, while minimizing tearout.

Block planes are also available in versions that suit specific work styles or applications. The No. 102 Apron Plane (left), gets its name from its compact size, which is a perfect fit both for your hand and for your apron pocket. It's perfect for quick spot planing tasks, edge chamfering and flush cutting. The Rabbeting Block PlaneThe (right), features open sides on both cheeks of the plane to reach into corners to take thin, precise shavings, leaving a perfect 90° angle and a surface like no other.

Expert Advice: What is the difference between a Jack Plane and a Low-Angle Block Plane?

Customer: I have a regular jack plane and a newer low-angle block plane. I find it much easier to use the low-angle plane. Can you tell me the difference, and does each style have its own specific use? Is there a style that you would recommend?

Tim Inman: Hand Planes 101: Is there a difference between a "regular" old plane and a low-angle block plane? Absolutely! Your observation is right. Usually, the low-angle block plane is easier to use. Each and every plane has its own design function. The block plane is especially different from most of the others. On most planes, the plane iron — the actual cutting part — is set with the cutting bevel facing down. They have a second part called a chip breaker that rides on top of the plane iron. It is spaced just a little bit behind the cutting edge. How much behind? It depends — on the operator, on the wood, on the plane, etc. The chip breaker setting is critical, and it is an "artistic" choice. A block plane does not have a true chip breaker. The bevel side of the block plane iron is set with the bevel facing up. A "regular" plane holds the plane iron up at a much steeper angle. A low-angle plane lets the plane iron lie down at a lower angle. Back in the day, carpenters wore bibs with a side pocket on the leg. The block plane was commonly found in one of those pockets. Handy, at the ready and versatile for use on about any job at hand. Still true today. Not many wear carpenter's striped bibs anymore, but lots and lots of tradespeople who work fine wood will have that little block plane close at hand still. Which one to use? I go back to my woodturning mentor and friend, Bill Jones. He endeared himself to me instantly at a teaching seminar one time when he was asked by a participant which tool he should use. Bill answered immediately and without hesitation: "The one that cuts," he said. I agree. Use the plane you like and the one that cuts. It isn’t the tool, but the smooth surface you're after. Use the one that cuts best for you.

Chris Marshall: I use my low-angle block plane for all sorts of applications. It’s great for leveling mismatched panel edges in a glue-up, trimming the ends of box joint pins, dovetail tails or wood plugs flush when they’re standing proud of a joint, taking the rough surface off of workpieces that are too small to run over the jointer and for general chamfering. This last task is where I probably use mine the most. Whenever I want to "soften" or "ease" a sharp edge but still want to keep the very fine facets of that edge (instead of just rounding it over with a router or abrasives), I reach for my block plane. Every woodworker needs a good block plane. I'll argue that it should be the first plane we buy, regardless of whether we consider ourselves dyed-in-the-wool machine tool users, “hybrid” woodworkers or a hand tool purists. It’s so versatile and easy to use! And if I had to choose between a low-angle block plane or a "regular" block plane again, I'd still choose the low-angle style. It seems to do everything a block plane should do for me.

Specialty Planes

Finally, there are a number of specialty planes designed for very specific purposes.

Expert Advice: Chooosing the Best Hand Plane for Your Projects

What Hand Plane Should I Buy First?

Customer: I am new at woodworking but eager to learn. I'm considering buying my first hand plane. Which one should I buy and what brand do you recommend?

Chris Marshall: Before you can determine which hand plane to buy first, the bigger question really needs to be what tasks you want to do with it. And that opens up the larger matter of what method of work you want to pursue in your woodworking: hand tools, power tools or a mix of both. You can carry out all of your surfacing and truing tasks with sharp planes, or you can do much of this work with power tools instead. For instance, a bench plane will flatten stock faces and reduce thickness, a jointer plane will flatten the edges and a block plane will square up the ends. So will a power jointer, surface planer and an accurately tuned table saw or miter saw. A smoothing plane can produce a finish-ready surface, but so can a sander and abrasives. I'm grossly oversimplifying things here, but you get the point. I think a well-rounded woodworker should eventually become adept at both methods of work, but honestly, I'm not there yet myself. I favor power tools but reach for my low-angle block plane and rabbeting plane for chamfering, cleaning up tenons and so forth. Someday, I hope to be equally skilled with a larger variety of hand planes … but for now I guess I'm a hybrid woodworker. There's always something new to learn. In terms of brands, I'll choose not to name-drop. There are a number of good hand plane manufacturers these days — not just one or two. Read some magazine reviews, check out hand tool forums and most importantly, try out some planes at a woodworking show or store. The ones that suit you best may not be the same brand and model as another woodworker suggests.

Tim Inman: If I could only have one plane, and I wanted to do "all-around" woodworking, I'd buy a good block plane. They're just handy for everything, and you should keep it in a really handy-to-reach place near your bench. Don’t hide it away. I'd buy the lowest angle plane I could (there are a couple of approaches to blade angles in block planes out there), and I'd pay as much as I could possibly afford. Then, the really important part: You must learn how to sharpen the blade, and KEEP IT RAZOR-SHARP whenever you use that plane. A good plane, well sharpened, will have a sound when you use it that is the key to knowing when you’re sharp enough. If your plane is sharp, it will "sing" as it cuts a curl. It will make you smile, and your work will be better for it. You'll want to use it again! Then, you'll start buying more planes whenever you see them. They're fun to have. You'll actually use the block plane, though.

More About Woodworking Hand Planes

Click to Learn More: How to Set Up and use a Hand Plane

VIDEO - How to Sharpen a Hand Plane iron

Click to Learn More: Spoke Shaves and Scrapers

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks