Video: Lathe Dust Collection System

Woodturners know that dust collection is challenge when working with a lathe. The Dust Right® Lathe Dust Collection System includes several tools to help improve your lathe's dust collection.

The centerpiece of the system is a C-shaped ''dust scoop,'' which wraps around spindle turnings to catch dust right at the source. Add to that a highly adjustable solid steel boom arm support system, a flex-form hose to connect to your dust collection system, and a chip deflector and you have an all-in-one package that will dramatically reduce the amount of dust in the air and on the floors of your shop.

Chris Marshall: It's pretty tough to get good dust collection on lathe. Probably tougher even than having it work well on your miter saw. When you're bull turning, there's just no good way to keep big chips and wet shavings from flying all over the place. Your odds of corralling that debris are a lot better when you're turning dry spindles like this, because you're working in a more confined area, the chips are smaller, and all of the turning is happening on the outside of the spindle.

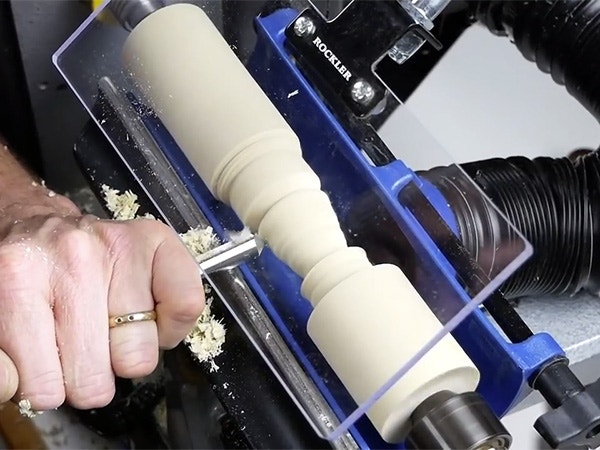

Rockler has a couple of dust collection products for your lathe than can help make your spindle turning a lot less messy. First, there's this lathe dust collection system. It features this 9 inch long plastic scoop with a 2.75 inch interior diameter than can partly wrap around the spindle you're turning. The scoop friction fits to this length of flexible hose that comes with the kit. You can attach the hose to a 4 inch diameter dust collection hose like I've done here if you buy an adapter.

This steel framework with a 15 inch long solid post lets you position the scoop at whatever height you need it based on the swing of your lathe. The scoop also rotates on this boom arm. The whole assembly attaches to your lathe bed with a plate under here and a star knob. This accessory should mount to any lathe with a bed opening that's at least an inch and a quarter. That's one dust collection accessory, and here's the other one.

It's a lathe chip deflector that Rockler sells separately. It attaches right to the steel post of the dust collection system. It's got this flexible steel goose neck that enables you to position this 0.25 inch thick clear deflector wherever you need it. That'll help keep the chips and debris coming up and hitting you in the face, but it also acts like a backboard to direct that debris back down into the scoop.

Now, maybe you're thinking about adding these two accessories to your lathe, but you're wondering, "How well do they actually work?" Well, I've got a poplar blank mounted between centers here on my lathe and the dust collection system is hooked up to my dust collector. Let's make some chips and see what happens. Here, I'm starting to rough the blank into a spindle, and the chips are following the big flute of the roughing gouge. Most of them aren't going down into the scoop.

That's because the flute is facing away and isn't really allowing them to, but the chip deflector is keeping the chips from flying up at me, which is nice. You can see that when I stop the lathe and push the chips down and out of the flute, the scoop is sucking them in. Now, I've got the spindle roughed out and it's time to switch tools. I'm going to use a standard spindle gouge. I'm just going to make some push cuts from the left and the right.

I'm not trying to make anything here besides a lot of debris. It helps that the spindle gouge's flute faces sideways for these cuts. Granted, I'm making some pretty aggressive cuts here. As you can see, not everything is going down the chute. It's hard to get a good vantage point with the camera to really see how much is being captured here, and quite a lot is. The closer you can get the scoop to the spindle and the more air your dust collector draws, the better the chute is going to work for capturing bulk chips and debris.

These carbide insert turning tools are really popular these days, so let's see how the dust collection system works with these. Back on the spindle again, I've got a flat-edge scraping tool and I'm just pushing straight in. Without any flute on the tool's shaft, the chips are just spilling right over the sides and down into the scoop. I'm finding that as the spindle gets smaller, the chip collection improves.

Here, I've got a circular scraper and I'm cutting a curve into my spindle. As you can see, most of the chips are headed straight from the tool into the scoop. Of course, the closer you are to the center of the scoop where the suction is coming from, the better the scoop is going to work. When the turning is done, we do a lot of sanding on our spindles too. Let's take a look and see how well the dust collection works when sanding.

I'm going to start sanding with my dust collector turned off just so we can see how much dust accumulates. As you might guess, it doesn't take long. This is the really fine dust that makes sanding on a lathe a nuisance at the least or even harmful to your health, and some of it is so fine we can't even see it. Now, let's try that again with the chip deflector cleaned up and the dust collector turned on. Here's proof positive of why dust collection on a lathe can really help at the sanding stage.

The dust isn't accumulating on the chip deflector or on the scoop. Now, these accessories aren't substitutes for wearing a good dust respirator too, but why not control and minimize dust however you can. If you're turning longer spindles like chair parts or table legs, you'll probably have to move these accessories up and down your lathe bed as you work. That might not be super convenient, but if you're turning smaller items like pens, duck calls, furniture knobs, or bottle stoppers, you won't have to move the scoop at all.

Either way, I think these two Dust RIGHT accessories could be a good solution for cleaner spindle turning at your lathe. I'm Chris Marshall with Woodworker's Journal Magazine. Thanks for watching.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks