Router Table Basics - A Quick Tour of Router Table Techniques

For as little as it takes to get set up, and the short time it takes to acquire skill at using a router table, it's easy to see why this venerable workhorse is often one of the first and most important tool purchases that a woodworker ever makes. Below, we'll take a quick look at the common woodworking procedures that you can master within the first few weeks of owning a router table, including:

- Working with long, narrow or small stock

- Edge trimming and template work

- Using a router table as a jointer

- Grooves, dadoes and slots

- Stopped cuts

- Dovetail and box joinery

- Making raised panel doors

- Lock-miter, drawer lock, and finger joints

Once you're up to speed on the basics of router table technique, we encourage you to move on to "Choosing a Router Table," where you'll find tips on what to look for in a router table, and help selecting one that's right for your shop.

Working With Long, Narrow, or Small Stock

Long and narrow stock is easily machined on a router table. Featherboards make it even easier; they hold the stock tight against the surface of the fence and table and let you can concentrate on a steady, even feed rate. In general, a router table will help you work with stock of dimensions that don't lend themselves to handheld router work. Long, narrow stock, such as that used to make moldings and trim are nearly impossible to work with a handheld router. Edge profiling a few hundred feet of a particular door or base molding could probably be done with handheld router and the aid of special shop-built rigging, but dong so would be an extremely inefficient choice, when a router table makes long runs of narrow stock routine. Small pieces of stock are also a challenge to work with a handheld router. Handheld work on small parts often involves a difficult balancing act. You have to keep the router perfectly upright on stock that doesn't do a good job of supporting the router base. To compound the problem, you have to have a way of holding the stock itself in place while you work. A router table leaves both of your hands free to hold on to small parts while the table surface provides a sturdy, flat support for the entire surface of the workpiece.

Edge Trimming and Template / Pattern Work

Trimming the edge of a piece of stock to a flat, smooth, square surface or exactly following the contour of a pattern is one of the router's specialties. Attaching a straightedge or a template to a piece of stock is one of the quickest and most effective ways to clean up an edge, or to perfectly and repeatably form the arched top of a frame and panel door or any other curved part.

Using a router table for edge trimming and pattern work speeds the process by eliminating the need to hold both the workpiece and the pattern down while you make the cut. The arched top of the door panel you see pictured here is being trimmed to the exact shape of a arched door template using a flush trim router bit in preparation for profiling with a raised panel bit. The router table surface supports the workpiece very well, and only a few seconds were expended attaching the template with double sided tape. With a handheld router, the door would have had to be clamped down a work-surface in preparation for the cut, and considerable care would have been required to keep the router surface flat on the surface of the panel.

Using a Router Table as a Jointer

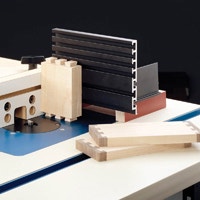

A popular question on woodworking forums asks, "can a router table be used as an edge jointer?" It sure can, and in fact, doing so is a popular space-saving and money-saving alternative to owning a dedicated jointer. With the Router Table Jointing Shims available for Rockler Router Tables and sized to fit the rockler router table fence bolt pattern, it takes only a few minutes to set up for edge-jointing.

Cutting Grooves and Slots

Cutting grooves, slots, dadoes and rabbets, sliding dovetails, mortises and tenons are all part of the router tables stock in trade. With a router table and a few basic router bits you'll be surprised what you can accomplish. Especially when you have multiple identical parts to cut, a router table can greatly speed these fundamental woodworking operations.

Stopped Cuts

Many woodworking operations call for stopped cuts - cuts that do not continue for the entire length of the stock. Stopped cuts can be either decorative, like a chamfer that begins and ends at a certain point on a table leg, or functional, as in the case of a mortise or a half blind dovetail pin. A router table can be set up in seconds to perform a stopped cut; the same operation with a handheld router or a table saw is often extremely cumbersome or dangerous. The Rockler router table fence makes setting up stopped cuts especially easy - its T-slotted fence facing allows quick and easy positioning of stops for perfect, repeatable cuts.

Dovetail and Box Joints

There are many ways to make dovetail and box joints and there are excellent dedicated dovetail jigs on the market. Using a router table to cut dovetails and box joints, on the other hand, has certain advantages. Most dovetail jigs are designed to help you make solid, accurate joints in a hurry, and because of that, only give you one or two options for the size and type of joint possible. In contrast, a router table can be set up to cut a wide variety of joint sizes and configurations. And with an affordable add-on like the Incra Universal Precision Positioning Jig, you can easily master impressive specialized decorative joints like the "corner post" dovetail you see being made here.

Raised Panel Doors

The parts used to construct a raised panel door can only be made on a router table (or a shaper). There are two reasons for this: First, the bits used to make raised panel door frames and the panels themselves are large diameter bits that take off a great deal of material in one pass. Using bits of this size with a handheld router is not recommended for safety reasons. Just as importantly, the stiles and coped ends of the door frames's rails have to be machined as near perfectly as possible for the door to glue up properly. Accurately milling the parts of a frame and panel door with a handheld router falls somewhere in between impractical and impossible. raised panel door parts With a router table, on the other hand, making raised panel doors is a relatively easy process. Even if you've never made a frame and panel door in your life, with a good set of frame and panel router bits, a few affordable router table accessories, and a little instruction, you can begin making successful frame and panel doors in the space of an afternoon. Add in a Raised panel bit and a door edge bit, and you'll be set up to make doors that look like they came straight from a high-end cabinet shop. To see just how easy the process can be, read Rockler's article Raised Panel Door Tools and Techniques. You'll find step by step instructions for making classic arched top raised panel doors, along with tips on which tools and techniques make the process easy and enjoyable.

Lock Miter, Drawer Lock and Finger Joints

A router table make available a number of specialized joinery operations that would otherwise be extremely difficult - if not impossible - to perform. Lock miter bits, drawer lock bits and finger joint bits are three examples of bits designed for use strictly with a router table and turn difficult and sometimes unreliable joinery methods into quick, accurate and durable work. lock miter router bit allows you to cut an interlocking miter that not only perfectly aligns the joint, but also greatly increases the performance and durability of the (surprisingly difficult) miter joint. Drawer lock bits address another difficult joinery task: joining drawer box members. The drawer lock bit gives you a quick and easy alternative to traditional dovetail joints for making reliable and accurately square drawers and other box shapes. router book If you ever run out project ideas for your router table, you'll find plenty more - along with in-depth information on router technique and safety - in any selection from Rockler's Router Book and DVD collection. A finger joint bit adds a "third dimension" to your wood joining arsenal. With a finger joint bit, you can tackle one of the most difficult joinery procedures of all, joining boards end to end. The exactly mating fingers cut by the finger joint bit create more than adequate gluing surface for end to end gluing, and can also be used for end grain to long grain joining.

And Much, Much More...

We've barely touched on the woodworking operations a router table makes available - there are many, many more. The possibilities are nearly endless, and the same goes for the variety of router bits designed strictly for use on a router table. With a little practice and a few router table projects under your belt, you'll become "router table literate" and a variety of practical applications will come to mind. Fortunately, the router table options Rockler makes available are plentiful, as well. Whatever your skill level, budget, or woodworking style, we're pleased to offer a router table that's perfect for you.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks