Intro to Turning

Have you ever watched someone turn a block of wood into a beautifully shaped piece and thought, That looks like fun—but hesitated because you assumed it was too expensive or complicated to start? Woodturning is a unique branch of woodworking with its own tools and techniques, and even seasoned woodworkers might feel like they're stepping into a whole new world.

The good news? Getting started is easier than you think! Here’s what you need to begin your woodturning journey.

You'll Need A Wood Turning Lathe

Buying a wood-turning lathe is an exciting step in your woodworking journey but picking the right one can be a bit overwhelming. Whether you're turning pens, bowls, or table legs, here are the key factors to keep in mind:

Distance Between Centers – How Long Can Your Workpiece Be?

This is the maximum length of wood your lathe can handle. It’s the distance from the headstock (where the motor is) to the tailstock (the adjustable end). For example, a wood turning lathe with an 18" distance between centers can turn pieces up to 18" long.

Swing Over the Bed – How Wide Can You Go?

Swing over the bed tells you the maximum diameter of the piece you can turn. This measurement is twice the distance from the center of the spindle to the lathe bed. A wood lathe with a 10" swing can handle turning blanks up to (just under) 10" in diameter.

Speed – Fixed or Variable?

Lathe speed is a big deal, especially for safety. Large-diameter blanks should spin at lower speeds to prevent vibration or the piece flying off.

Fixed-speed lathes – These offer preset speeds. To change the speed on a fixed speed lathe, you need to manually move the drive belt to a different pulley on the motor or spindle.

Variable-speed lathes These allow smoother adjustments, giving you more control while turning. If you plan on tackling a variety of projects, variable speed is a great feature to have. Rockler’s 12-24 variable speed midi lathe is a customer favorite and a great choice for new woodturners.

Horsepower – Do You Have Enough Power?

The size of your motor determines the cutting power you’ll have. Here’s a rough guide:

Mini Lathes – Rockler's 1/2 HP mini lathe is perfect for small turning projects like small table legs, ice cream scoops, pens, bottle openers, rings and so much more.

Midi Lathes – Typically range from 3/4 HP to 1-1/2 HP. Midi lathes offer increased turning capacity over Mini Lathes. Perfect for medium-sized projects like bowls and spindles.

Full Size Lathes – Usually 1-1/2 HP and up for handling large pieces with ease. Full-size lathes are primarily used by professional woodworkers who need to create large pieces like furniture components.

Spindles & Thread Sizes – Don’t Overlook the Small Details

Once you pick a lathe, you’ll need turning accessories like pen mandrels and lathe chucks. Pay attention to:

Morse taper MT-1 or MT-2 refers to the taper size of the headstock and tailstock spindles. MT-2 is the most common.

Headstock spindle size & thread count – Common sizes include 3/4" x 16 TPI, 1" x 8 TPI, and 1-1/4" x 8 TPI. Getting the right fit ensures compatibility with accessories.

You'll Need Turning Tools

Turning is a subtractive process – you create by removing material to reveal and shape the final form. Like a carver or sculptor, you need the proper turning tools to achieve the design and details you want. In turning, you have two broad categories of options in terms of tools: traditional turning tools and carbide turning tools.

Traditional Woodturning Tools - are typically crafted from high-speed steel (HSS). They’re versatile and offer great control but require frequent sharpening or replacement due to the shorter edge life. Traditional lathe tools are also difficult for beginners to master.

Carbide Turning Tools - are lathe tools that feature replaceable carbide inserts instead of traditional high-speed steel cutting edges. These tools are easy to use and don’t require sharpening. When the edge dulls, you simply rotate or replace the carbide insert.

Here's a brief introduction of the most common woodturning tools

Gouges: There are three main types of gouges: roughing gouges (also called spindle roughing gouges), bowl gouges and spindle gouges (also called detail gouges). The tools' names hint at the important differences between them.

Roughing gouges and spindle gouges are used in turning spindles, which involves stock that is usually longer than it is wide and is mounted in the lathe with its grain direction parallel to the turning axis. Roughing gouges are used to take stock from square to round. Spindle gauges are used for creating coves, beads and other details. In spindle turning, the lathe's tool rest is typically positioned close to the stock, supporting the tools close to the cutting edge.

By contrast, bowl turning blank are usually mounted in the lathe with its grain direction perpendicular to the turning axis, and the tool rest sometimes must be positioned several inches from the stock. As a result, bowl gouges are machined with higher walls and deeper flutes to stand up to the increased stress they face because of the increased overhang at the tool rest.

Skew chisels: With their angled cutting edge, these turning tools are used in spindle turning to make smooth shearing cuts and to form V-grooves and beads. They're available in a number of sizes and shanks. The angled cutting edge can be straight or curved. Many wood turners find that a fair amount of practice is needed to master the skew chisel.

Parting tools: These V-shaped tools are designed to cut or "part" off a finished spindle turning from the rest of the blank. They are available with either rectangular or diamond-shaped shafts, as well as in especially thin versions. Parting tools also are commonly used to cut grooves for marking cutting depths on spindle turnings with varied profiles.

Specialty turning tools: These include other tools such as scrapers and tools with cutter profiles designed to cut bead details or to shape the dovetailed recesses required for securing the bottoms of bowl blanks to an expandable four-jaw chuck.

You'll Need To Think About Safety

To grasp the importance of proper safety equipment and practices, it might help to remember that woodturning essentially involves poking a sharp metal tool at a hunk of wood that's spinning really fast. You want to do what you can to keep anything from flying off the lathe and to protect yourself in case something does.

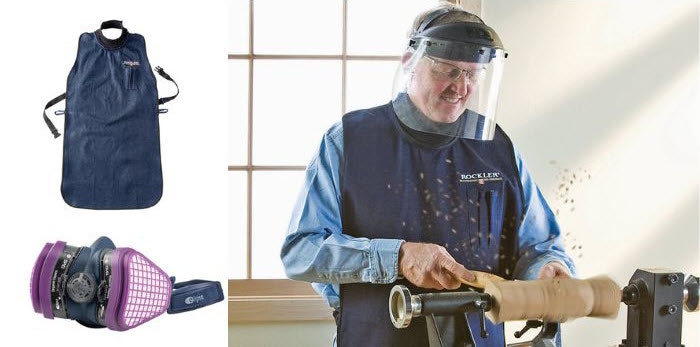

At minimum, you need:

A face shield - Not just goggles; they can't stop a chunk of walnut burl from whacking you in the nose.

Dust collection and respiratory protection - wood dust exposure has been linked to allergic skin reactions, respiratory issues and even cancer.

A Wood Turner's Apron - If you want to protect your clothing and keep shavings from going down your shirt.

Besides having the right safety gear, if you have long hair, be sure to tie it back. Roll up long sleeves and remove anything that might catch in the lathe, such as necklaces and rings. Make sure that your turning stock is mounted securely in the lathe and balanced to avoid excessive wobbling.

Be sure to run the lathe at the appropriate speed for the stock you are working with. If the lathe starts walking across the bench or floor, slow down. Keep the tool rest close to the stock to reduce the chance of tool's getting caught between the tool rest & the workpiece. Make sure the lathe is set up at the right height for you. Ideally, the center of the spindle should be at elbow height. Before sanding, remove the tool rest and when sanding, hold the abrasive to the bottom of the workpiece, where the direction of the spin is away from you.

You'll Need Turning Blanks

Obviously, you have to have something to turn. In theory, you can turn any piece of wood that will fit on your lathe, so long as it's sound and doesn't have any loose knots or other structural defects that might cause it to come off the lathe. For beginners, though, precut turning blanks are perfect.

Once you get a little experience, you can branch out. You can salvage good turning stock from your firewood pile or make your own turning blanks using resin and silicone casting molds

SHOP

- Pen Blanks

- Pen Blank Casting Molds

- Ring Blank Casting Molds

- Handle Blank Casting Molds

- Epoxy Accessories

Turning Project Kits & Hardware

Turning project kits are pre-packaged sets that include the necessary hardware and components to create a specific turned item using a lathe. These project kits make it easy for woodturners to craft functional and decorative items without having to source all the individual parts themselves. Bring your ideas to life with these popular project kits.

Pen Kits – One of the most popular options, these kits contain pen tubes, ink refills, clips, and other hardware needed to turn a custom wooden or acrylic pen.

Bottle Stopper Kits – Includes metal stoppers with threaded inserts, allowing you to turn a custom handle.

Garden Turning Kits – These kits includes everything you need to create handles for popular gardening tools. These make a great gift for the gardener in your life.

Ice Cream Paddles & Pizza Cutter Kits – Contain stainless steel scoop or cutter heads that attach to a turned wooden handle.

Start Your Woodturning Journey With Confidence

Rockler has everything you need to start your woodturning journey with confidence. From high-quality turning tools and lathe accessories to essential safety gear and expert guidance, you’ll be shaping wood into beautiful, handcrafted pieces in no time!

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks