Video: How To Resaw Lumber With A Band Saw

Resawing lumber is cutting the stock lengthwise along the edge. Resawing a board creates a thinner piece of stock. This technique is used to make thin panels, such as veneer, and also to make book match panels. Learn how to choose the best band saw blade and band saw fence to resaw a board. A wider blade is best for resawing. Choose a 3/4-in.-wide band saw blade for most 14-in. band saws and choose a 1-in.-wide blade for most 15-in. band saws.

More Tips for Resawing Lumber

The best tool to slice thin pieces of wood from bigger pieces of wood is a band saw. But, what's the benefit? Why not buy your wood sliced thin to begin with, or just plane or sand it to thickness? Here are five good reasons to resaw lumber.

1. You’ll get the best use out of expensive or beautifully figured wood.

2. You'll be able to create book-matched, slip-matched or swing-matched panels.

3. You'll have a method to efficiently use salvaged or reclaimed lumber of large dimension.

4. You'll be able to create your own lumber from a tree (or even from firewood).

5. 5. When you get good at it, you can make your own handmade plywood.

Equipment Makes a Difference

To get started with resawing, I recommend a band saw of sufficient power and with a large depth of cut. Any motor smaller than 1hp and depth of cut less than 10" will limit your effectiveness. (Some 14" band saws have about a 6" maximum cut...so you'd be limited to a 12" wide book-matched panel or less.)

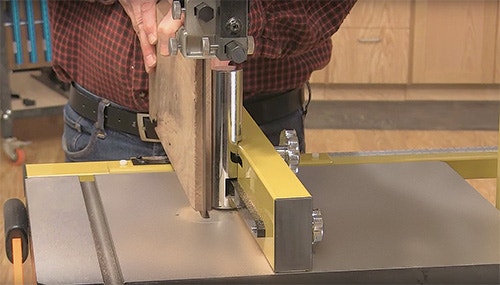

I also recommend using a point fence of some sort. By having a single point to register the cut (placed adjacent to the cutting edge of the saw blade), you will be able to swing your stock left or right to correct for blade drift. You might be able to get away with using a standard fence once in a while, but if you're trying to slice off a 1/4" piece of expensive hardwood, and your blade drifts toward the fence, you are powerless to correct it.

And, speaking of saw blades: the rule of thumb for resawing is "the wider the better." Wider blades, 1/2" and larger, cut straighter, which is the goal. Also, fewer and larger teeth per inch make for better resawing.

The question that I often hear is, "Can you resaw using a narrow band saw blade?" I always answer, "Sure. And you can hunt buffalo with a BB gun, too." In both cases, you're asking for trouble!

When it comes to resawing blades, think wide and dentally challenged. Fewer teeth per inch allow the blade to remove sawdust more effectively. And if you are slicing through a 10" or 12" board, you can imagine how much waste that makes. Three teeth per inch is often identified as the sweet spot for resawing. And wider blades just track better and cut straighter — exactly what you want when resawing.

Laguna Tools' Torben Helshoj has created his own resaw blade design, dubbed the Resaw King. It has carbide teeth, excellent steel and is a real performer. But even if you don't opt for a "specialty" resaw blade, stick with a wide and open-toothed blade to enhance your resawing activity.

Resawing By the Numbers

Resawing Step-By-Step Overview:

1. Square up and surface two faces of your lumber. While it's possible to resaw rough-cut lumber, your work will be more accurate and easier to control if you first prepare the stock.

2. Use a point fence. You can easily make or buy one. Many of the larger band saws come with a screw-on fence attachment for this purpose.

3. Set the fence to the thickness of the stock you require. Be sure to accommodate the saw kerf in your planning. For example, it's impossible to get three 1/4"-thick pieces of stock from a 3/4" piece of wood. The two saw kerfs eat up close to 1/8" of wood.

4. Adjust the upper blade guide to the width of the board you are resawing.

5. It is a good idea to scribe a line the width of the slice you are removing on the top, visible edge of the board. This will help you keep the saw blade exactly where you want it during the cut.

6. Use a push stick to finish the cut, when you slice off the slab of wood.

7. If you are making multiple resaw cuts in a piece of lumber, decide whether you need to run the face of the stock over your jointer or not.

8. Use a planer with a slave board to remove the saw cuts from the faces of the thin resawn slabs. A surfacing drum sander also works well for this task.

Q&A: Why is My Band Saw Stalling When I Resaw Boards?

I have been having a problem with my resawing and was hoping for some help. I put a new blade on my band saw yesterday, and I think the guides were out of alignment and bent the blade. My problem is, during resawing, the saw loses power when you feed the wood through that should go through easily. It takes forever to resaw a 4-in. piece, and if I try to feed it through under pressure I get the blade being forced into the guides. The rubber on the upper wheel did come off, but the blade is nice and tight so I don't think that is why the saw is losing power when I start to resaw. Any help would be greatly appreciated. It has a 5 hp motor so it shouldn't bag out. – Dave

Tim Inman: Wow! Something is wrong with this picture. Is there any chance the blade has been turned inside out and installed so the teeth are pointing in the wrong direction to make the cut? The teeth should be pointing down, in the direction of travel of the blade. It is actually very easy to get things turned inside out so the teeth point up or away from the blade travel direction. Check this out right away. If the blade is mounted so the teeth are pointing in the wrong direction to make the cut, it would take tremendous pressure to get the job done.

If that isn't the trouble, then do check the guide alignment, of course. What's dragging? Cut something small and thin - easy. See if it all goes well. Does it pass? Cut something thicker. Does it pass the test again? Ramp up until you run into resistance. Maybe you have a bearing that is getting ready to retire and doesn't handle the big loads so easily anymore.

Chris Marshall: Dave, is there a chance that when the guides bent the blade, they also knocked the "set" out of the teeth? By set, I'm referring to the way the teeth are tipped left and right when viewing the blade front to back. It wouldn’t take many revolutions with the blade dragging against steel for it to lose its set. Once the set is gone, the blade will cut poorly. A 5-hp band saw is a mighty machine, indeed. It should have an abundance of power to resaw 4-in. stock, and there should be no fading when pushing the stock through. Even if you are using a fine-tooth blade (not the best for resawing), if it's sharp, it should still resaw stock that narrow without any difficulty.

Here's another possibility to check: is the drive belt between the motor and the lower flywheel pulley sufficiently tight? I once did a band saw review in our magazine, and one of the machines suffered from this very problem: the belt was slipping on the lower pulley because it was tensioned too loosely at the factory. It wasn't apparent immediately; the belt hides behind the lower flywheel, and it didn't squeal in spite of the slipping. But, once I discovered the problem and tightened that belt, the saw resawed with the best of them.

If the blade is installed properly and in good shape, and the drive belt is tight, I'd be inclined to get the saw's motor inspected by an electrician or motor shop. It might be in need of some professional help.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks