Cutting Box Joints

Box joints might not be the most interesting or attractive joints, but they are very sturdy and simple to cut in most shops. Although not quite as iconic as dovetails, box joints are versatile for all kinds of projects. They don’t mechanically interlock like dovetails, but box joints do have lots of surface area, so they’re very strong when glued together. You can use them to build attractive boxes and trays, good-looking drawers and carcasses, and tool totes and chests strong enough to withstand daily use.

What is a Box Joint?

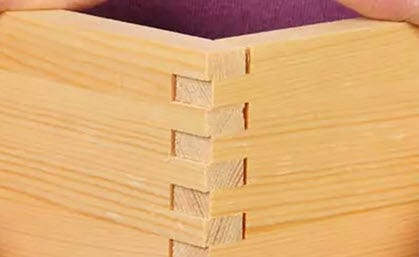

The box joint pattern of straight pins and slots that mesh together provides a geometry that will make non-woodworking observers wonder how you did it, and the light-to-dark interplay of face and end grain catches the eye every time. But aside from eye candy, these joints are as much substance as show. All of those contact surfaces between the pins and slots offer a huge amount of glue surface area.

Box joints feature interlocking straight pins and slots (photo above). Box joints are best for joining two frame or carcass members to form a corner — typically a right angle. But they occasionally also are used to create corners having other acute or obtuse angles.

The interplay of face grain and end grain in a pattern of repeating geometry is part of the timeless appeal of box joints. They also offer significantly more long grain surface area than butt joints, which delivers strong glue assemblies.

Box Joints vs. Finger Joints

Box joints are sometimes confusingly referred to as "finger" joints. A finger joint actually features a series of tapered finger-like pins and corresponding notches that interlock to joint two parts together. They're best used to scarf frame or panel members end to end, to form longer members. Finger joints are a solution for creating parts longer than the stock you have on hand — for instance, for a crown molding that traverses the entire length of a kitchen or den. Finger-joined scarf joints are also commonly used in boat building and for forming the gunwale on a canoe or sailboat. And if you buy prefab furniture or other sorts of laminated lumber panels, you might see finger joints used there, too.

Finger joints typically have tapered pins that fit into angled slots, and they're machined with a large router bit or a shaper cutter. These joints are commonly used to scarf workpieces end-to-end to make longer parts. Cutting finger joints requires a special hefty router bit in a router table or a finger joint cutter installed in a stationary shaper.

How to Make a Box Joint

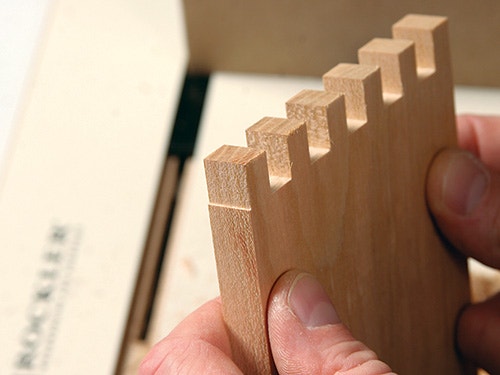

A box joint's pin-and-slot pattern requires an exacting tolerance in order to fit together well. Each pin must be cut to a width that fits the corresponding slot on the mating workpiece. If it's even a tad too tight, the two won't mesh together. And cumulative error can compound assembly problems even more. So, while box joints could be cut by hand, they rarely are. A variety of jigs can do the job faster and more accurately.

Cumulative error, resulting from tiny variations in the jig, blade or bit, can result in some degree of mismatch at the end of a box joint pattern. Here, it's evidenced by a tiny ledge on the part edge that will be trimmed away.

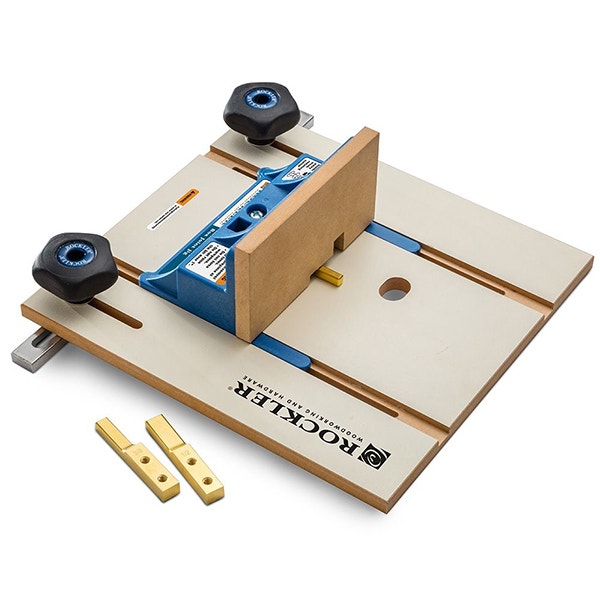

Making Box Joint with a Router Table and Box Joint Jig

A sliding router table jig, such as the Router Table Box Joint Jig (above) works with any router table with a miter slot. The jig's sliding fence holds the workpiece vertically and guides it over the router bit. This jig features interchangeable brass indexing keys to index each slot location with a straight router bit. By switching indexing keys and router bits, you can use this jig to cut 1/4-in., 3/8-in. or 1/2-in. box joints. For larger projects, the Router Table XL Box Joint Jig will cut 1/2" and 3/4" box joints.

The smooth-sliding sled features long ''skis'' that keep it square to the bit and tabs on the bottom that stop the sled at the end of the cut. Lock it into the miter slot of your router table with our comfortable Easy-to-Grip knobs and you're ready to rout.

Making Box Joints with a Table Saw and Jig

The most common and economical option for cutting box joints with a table saw is to use a simple scrap-made jig that fits on a miter gauge. It amounts to a scrap fence with a short pin that protrudes out from it. The width of this pin matches the width of the pins the jig produces. The jig is positioned and fixed to the miter gauge such that the pin is one pin distance away from the router bit or dado blade that will cut the corresponding slot for the joint. As each slot is cut, the workpiece is reset on the jig with a slot fitted over the jig pin. A series of repeated passes, shifting the workpiece each time, creates the joint pattern.

Common box joint jigs consist of a scrap fence with a protruding pin attached to a miter gauge. They are easy to make and can be used either on a table saw with a dado blade or on a router table with a straight bit.

Free Box Joint Blanket Chest Plan

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks