How to Cut Loose Tenon Joinery with Biscuits, Joiners & Mills

Cutting loose tenons is made much easier with tools designed to allow you to make those cuts from specialized jigs to biscuit joiners to mortise joiners. If you’ve ever used dowels to join wood, you already have experience with loose tenon joinery. Loose tenons can be used any place you’d use a traditional mortise and tenon and, with some of these tools, many other places, too. The tools in this story make joinery much easier than a doweling jig.

With prices ranging from $30 to $775, it’s up to you to pick which makes the most sense for your shop and your checkbook. (Note: the biscuit joiner I used represents biscuit joiners as a group, rather than being evaluated as an individual model.)

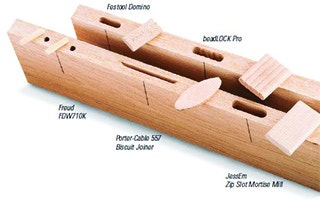

Loose Tenons Vary Among Tools

Each tool creates a different type of mortise, the biscuit joiner creates the most shallow penetration. The loose tenons vary among the tools. The Freud machine bores holes for dowels. The Festool, beadLOCK and JessEm tools make wide and deep slots, and biscuit joiners cut wide but relatively shallow slots. From a strength-of-joint perspective, I like the deep mortises I can get from Freud, Festool, beadLOCK and JessEm.

All of these tools provide deeper penetration into the mating pieces than a biscuit joiner does. Deeper penetration provides greater resistance to racking and breaking. Imagine kids jumping on the bed you assembled with loose tenons. Long tenons (deep mortises) make more structural sense than short ones.

How They Work

Let’s have a look at the basics of how these different tools make their mortises. There are two versions of the beadLOCK jig available, but their basic functions are similar. Each allows you to drill a series of overlapping holes. You’ll drill three holes with the drill guide in position one, then two more with the guide side shifted to position two. Stops make it easy to hit both positions perfectly. The three holes on the left end of the guide are used when drilling one part of the joint, and the other three holes are used when drilling the mating part. The drill guide in the Basic beadLOCK has just three holes.

The two JessEm Zip Slot Mortise Mills also rely on a handheld drill, but it’s used differently. The drill bit that comes with the Mills looks a lot like a router bit. Make a mortise by pressing down lightly on the running drill and moving the jig’s handle back and forth. Each pass back and forth becomes progressively deeper, creating a mortise in the workpiece. There are a variety of ways to use biscuit joiners and the Freud and Festool machines, but the most common is to register off the fence, as shown at bottom right. An index line on the tool is aligned with the layout line on the work, and you’re ready to cut. Depth of cut is controlled by a plunge stop on the tool.

Making Assembly Easy

Three of these tools — biscuit joiners, JessEm and Festool — allow you to cut a mortise that’s longer than the loose tenon material. This allows for some side-to-side adjustment, while maintaining accuracy up and down. Imagine you’re using a number of loose tenons to fasten a solid-wood edge to plywood. If you miscut the position of any one of the mortises, you may not be able to assemble the joint. On biscuit joiners you get what you get; you can’t control the length of the mortise. With JessEm and Festool, you can control the width so that if you want a tight fit, you can make that happen. If you want a slightly longer mortise, you can make that happen, too.

The Freud FDW710K machine doesn’t make elongated cuts, but then, it doesn’t really have to. Along with the Festool Domino, the Freud has been designed to make accuracy much easier. With them, you can make one cut, then seat a spring-loaded pin on the machine in that cut to locate it for the next cut. Indexing is pretty automatic. The pin is built into the FDW710K, and it is an accessory ($60) for the Domino. This spring loaded pin is a great feature that means you only have to lay out the position of one joint, from which you can accurately index for other cuts.

Reinforcing Miters

Three machines — biscuit joiners, FDW710K and the Domino — allow you to reinforce an angled cut. These tools have fences that can be set at a variety of angles. JessEm and beadLOCK, on the other hand, are designed to be used when the edge you’re cutting the mortise into is perpendicular to the face.

Joining Small Stuff

The last thing you want is for a mortise to show through the edges of your workpiece. The narrowest piece any biscuit joiner can be used on, even using a small #0 biscuit, is 2-1⁄8". So, if you want to use loose tenons to assemble a 1-1⁄2"-wide face frame, biscuits aren’t your answer. All of the other machines will do it. On the FDW710K, one boring bit can be removed so you can locate the single remaining hole wherever you want for tighter spacing. beadLOCK and JessEm tenon material can be ripped to provide narrower pieces for shorter mortises. And the narrowest Domino tenon is about 3/4" wide.

Some biscuit joiners are capable of accepting a smaller diameter cutter that will allow biscuit slots in narrower pieces — but if the machine wasn’t designed for this, it can’t be done. If you’re in the market for a biscuit joiner, this is a feature worth looking for. If you’re looking to create a butt joint in a case, you’ll need mortises in the middle of a piece. Biscuit joiners, along with the FDW710K and Domino, will do this work, allowing you to use loose tenons in place of dadoes.

Biscuit Joiners

A good example of biscuit joiners on the market right now is this Porter-Cable 557, which makes fast, easy to use but shallow cuts for joints. Prices range from about $100 to $999. The Porter Cable 557 shown here costs about $210.

For biscuit and similar joiners, use a layout line to locate where you will make your cut, and plunge the tool through the length of the line to cut the mortise. Biscuit joiners have been around and getting attention for a long time. They’re fast and easy to use. My two biggest complaints with them are their shallow penetration into the mating pieces and the length of the slots, which limits their use on narrow parts. I’d love to see side-to-side indexing added to biscuit joiners, like that found on the Freud and Festool machines.

Summing Up

Loose tenons come in several sizes, the bottom piece is 2-1/8" wide with a #0 biscuit, but another tool would make a better cut for narrower stock. With the range of prices on the tools in this article, there’s got to be something here that fits your wallet. So, let’s sum up the features and benefits. You just can’t go wrong with the beadLOCK Basic Kit. It’s inexpensive, and you’ll get lots of joinery out of it. But, as with the other beadLOCK jig and the JessEm Pocket Mill, you’ll be testing your eyes each time you locate the jig on your layout lines.

The large Zip Slot Mill is easy to index on your work, and can cut a versatile array of mortise sizes. The beadLOCK Basic and JessEm Pocket Zip can’t get a mortise in the center of a 4 x 4. Any of the other tools can. Biscuit joiner models are plentiful, there’s probably one in your price range, and they’re pretty intuitive to use. But, as you’ve seen, they’ve got their limitations. The Festool Domino and Freud FDW710K take a bigger bite out of your checkbook but provide more functionality. The ease of indexing from one cut to another is a great benefit, and you’ll certainly get the most versatility out of these machines.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks